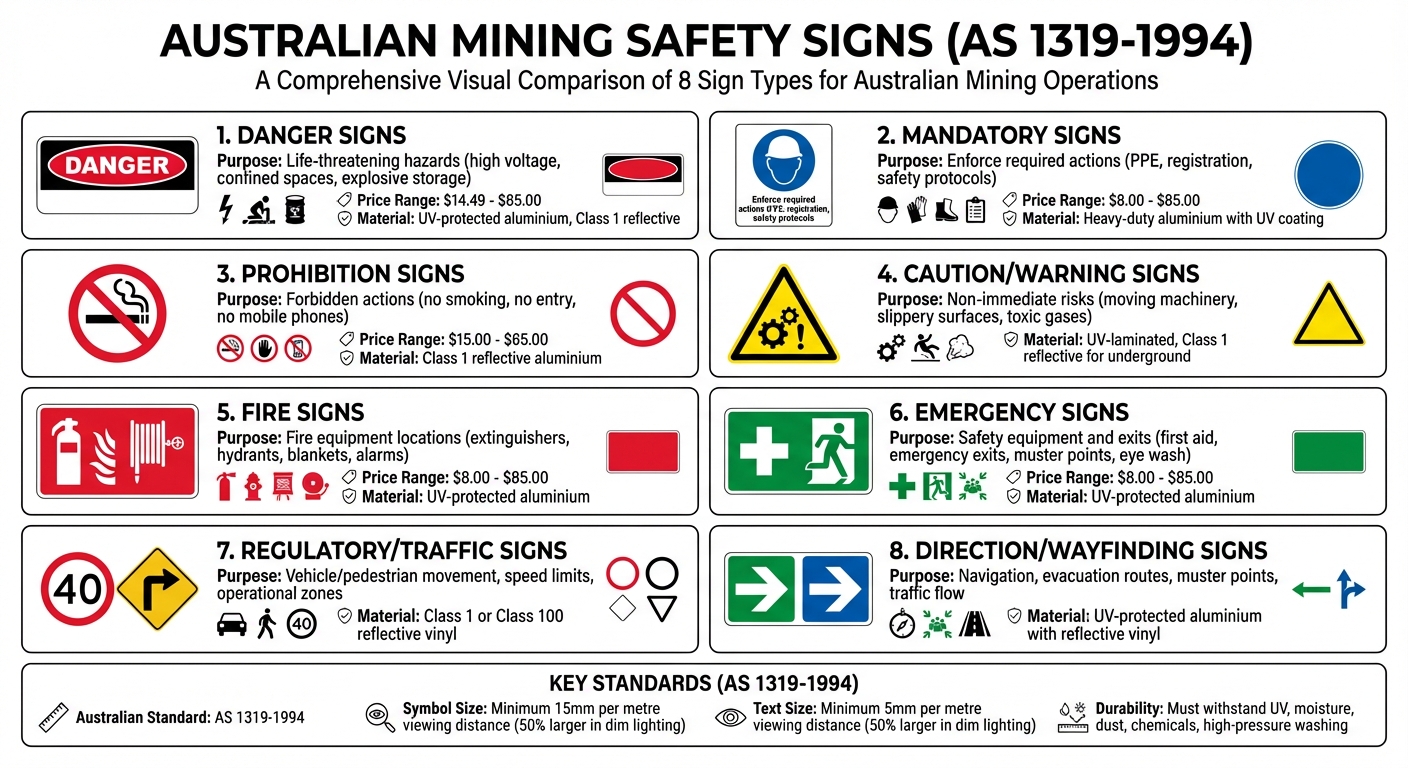

Mining Safety Signs: Types and Uses

Mining sites are hazardous environments, requiring clear and durable safety signage to prevent accidents and guide workers. Australian standards like AS 1319-1994 ensure safety signs are consistent, visible, and compliant. Here’s a quick rundown of the main types of mining safety signs:

- Danger Signs: Warn of life-threatening hazards like high voltage or confined spaces. Must feature white text on a red oval and withstand harsh conditions.

- Mandatory Signs: Enforce actions like wearing PPE. Recognisable by their blue circle design.

- Prohibition Signs: Indicate forbidden actions, e.g., "No Smoking" or "No Entry." Designed with a red circle and slash.

- Caution and Warning Signs: Highlight non-immediate risks such as slippery surfaces or moving machinery. Use yellow backgrounds with black symbols.

- Fire and Emergency Signs: Direct workers to exits, fire equipment, and muster points. Emergency signs are green, fire signs are red.

- Regulatory and Traffic Signs: Manage vehicle and pedestrian movement, ensuring safe operations.

- Direction and Wayfinding Signs: Guide personnel and vehicles, especially during emergencies.

- Custom Signs: Tailored for site-specific needs, such as unique hazards or protocols.

Durability is key – materials like UV-protected aluminium and reflective coatings ensure signs remain visible and effective in tough mining conditions. Regular maintenance and compliance with Australian standards are essential for worker safety and legal adherence.

8 Types of Mining Safety Signs: Visual Guide to Colors, Symbols and Uses

1. Danger Signs

Danger signs play a critical role in warning workers about life-threatening hazards before they enter dangerous areas. These signs are used to highlight zones where conditions could pose fatal risks – such as high-voltage areas, explosive storage sites, confined spaces requiring permits, or locations with hazardous atmospheres [1].

According to Australian Standard AS 1319-1994, the word ‘DANGER’ must appear in white on a red oval, set against a white background that specifies the particular hazard (e.g., ‘HIGH VOLTAGE’ or ‘CONFINED SPACE ENTRY BY PERMIT ONLY’). This design ensures immediate recognition [1].

The effectiveness of these signs depends not only on their design but also on their durability and size. In mining environments, signs must endure harsh conditions, including exposure to moisture, dust, chemicals, and intense UV radiation. Heavy-duty aluminium with UV-resistant coatings is a popular choice, with basic models starting at approximately $14.49, while larger, reflective versions can cost up to $85.00 [2]. For underground settings, where lighting is limited, Class 1 or Diamond Grade reflective materials are recommended to maintain visibility. To ensure readability, symbols should be at least 15 mm per metre of viewing distance, and uppercase text should measure no less than 5 mm per metre. In poorly lit areas, these dimensions should be increased by at least 50% [1]. Placement is equally important – signs should be mounted at eye level, near the hazard, and against a contrasting background for maximum visibility.

Custom danger signs are often necessary to address site-specific risks, such as designated UHF communication channels or unique overhead clearance measurements. These customisations must still adhere to AS 1319’s strict guidelines for colour and layout. Regular maintenance is vital – any signs showing wear or damage must be replaced immediately to ensure ongoing safety.

For durable, high-quality danger signs tailored to the demanding conditions of mining operations, PXP Safety offers a wide selection of compliant and customisable options designed to meet your needs.

2. Mandatory Signs

"Mandatory signs don’t just suggest – they instruct." – Corsign [3]

Mandatory signs play a crucial role in mining operations by enforcing required behaviours. Whether it’s wearing PPE, registering upon arrival, or adhering to other safety measures, these signs ensure that essential safety protocols are consistently followed to maintain compliance and protect workers.

According to AS 1319-1994, mandatory signs are designed to be easily recognised. They feature a blue circle with a white pictogram, set against a white background with black text [1]. Common examples include instructions like "Wear Safety Goggles", "Hearing Protection Must Be Worn", or "High-Visibility Clothing Required." Site-specific signs might include messages such as "All Visitors Must Register at Office" or directions to locate MSDS (Material Safety Data Sheets).

To ensure visibility, the symbols on these signs must measure at least 15 mm per metre, with uppercase text no smaller than 5 mm per metre. In dimly lit areas, these dimensions must increase by 50% [1]. The materials used for the signs are equally important. Heavy-duty aluminium with UV-resistant coatings is ideal for withstanding the harsh conditions of mining sites, including exposure to moisture, dust, and chemicals. Standard mandatory signs are priced between $8.00 and $15.00 (excluding GST), while larger reflective aluminium options (600 mm × 600 mm) typically cost between $65.00 and $85.00 [2].

For unique operational needs, custom mandatory signs can be created. These may combine multiple instructions, such as "Hearing and Eye Protection Must Be Worn", or include site-specific protocols like permit-to-work requirements. However, even customised signs must adhere to AS 1319’s strict guidelines for colour, layout, and design to ensure compliance [2][6].

If you’re looking for mandatory signs that can endure the tough conditions of Australian mining sites, PXP Safety offers durable, customisable options. Their signs feature UV protection and outdoor-grade printing, ensuring they remain reliable over the long term.

3. Prohibition Signs

"Prohibition signs indicate that an action or activity is not permitted. Its designated symbolic shape is a red circle with a diagonal red slash through it." – WorkSafe ACT [1]

Prohibition signs are essential in mining operations, serving as unmistakable visual warnings to prevent actions that could lead to serious hazards like explosions, fires, or unauthorised access. These signs act as a clear deterrent against behaviours that might compromise safety or interfere with equipment.

As outlined in AS 1319-1994, prohibition signs are designed with a red circle and diagonal slash over a black symbol on a white background [1]. Examples include "No Smoking" signs near explosive storage areas, "No Entry" signs at active blast zones or confined spaces, and "No Mobile Phones" signs in areas where signals might disrupt sensitive equipment [3].

Given the harsh mining environment, these signs must endure moisture, dust, and exposure to chemicals without losing their clarity [3]. To ensure visibility in dimly lit tunnels, Class 1 reflective aluminium is commonly used. This material enhances durability and keeps the message visible even under low light. Basic prohibition signs are priced from approximately $15.00 (ex. GST), while heavy-duty reflective aluminium options (450 mm × 450 mm) are available for around $65.00 [2].

Custom prohibition signs, such as "No Entry to Workshop – Staff Only", must also adhere to AS 1319 standards [2]. Regular inspections are crucial – any faded or damaged signs should be replaced immediately to maintain their effectiveness [3]. For maximum impact, signs should be mounted at eye level and placed against contrasting backgrounds.

PXP Safety provides prohibition signs specifically designed for Australian mining conditions. These signs feature UV protection and outdoor-grade printing on durable aluminium, ensuring they meet the requirements of AS 1319-1994.

4. Caution and Warning Signs

Caution and warning signs play a critical role in alerting workers to hazards that, while serious, typically don’t pose an immediate life-threatening risk. These signs are essential in mining environments, addressing dangers like moving machinery, overhead loads, slippery surfaces, and toxic gases. Their purpose is to encourage precautionary measures before entering certain areas or operating equipment. To be effective, they need to combine clear, recognisable designs with materials tough enough to endure the harsh mining conditions.

According to AS 1319-1994, caution signs must adhere to specific design standards. They feature a yellow background with a black triangle enclosing a black symbol or pictograph. For underground mining, where lighting is often limited, these signs are adapted to maintain visibility without deviating from the standard’s guidelines [1].

The material used for these signs is just as important as their design. Mining environments expose signage to constant moisture, dust, chemicals, and high-pressure cleaning. To stand up to these conditions, signs must resist peeling, cracking, or fading. Aluminium with Class 1 reflective properties is a popular choice for underground use, while UV-laminated materials are preferred for open-pit sites to ensure they last under intense sunlight.

"The physical appearance of the safety warning may inadvertently communicate hazard severity." – Marc Green, Visual Psychologist and Safety Expert [4]

When signs become faded or damaged, they can unintentionally downplay the severity of a hazard, putting workers at risk. Regular inspections are essential to ensure all signs remain legible and vibrant. Any sign showing signs of wear, such as loss of colour or readability, should be replaced immediately [1].

Caution and warning signs are a vital part of a broader safety system, complementing other measures to keep workers informed and protected. Companies like PXP Safety offer customisable options, including UV-protected and durable aluminium signs, tailored specifically for Australian mining conditions.

5. Fire and Emergency Signs

Fire and emergency signs play a critical role in crisis management within mining operations, guiding workers to safety equipment, exits, and muster points. In Australia, these signs must adhere to AS1319-1994, which ensures a consistent visual system using standard colours and symbols. Emergency signs are designed with a green background and white text or symbols, marking areas such as first aid stations, emergency exits, safety showers, eye wash stations, and muster points. On the other hand, fire signs feature a red background with white symbols, indicating the location of fire extinguishers, hoses, blankets, hydrants, and alarms.

The AS1319-1994 standard also specifies size requirements for visibility. For instance, a sign meant to be seen from 10 metres away should feature symbols that are 150 mm tall under normal lighting and 225 mm tall in dim conditions.

| Sign Type | Background Colour | Text/Symbol Colour | Mining Applications |

|---|---|---|---|

| Emergency Information | Green | White | First aid stations, emergency exits, muster points, eye wash stations |

| Fire Signs | Red | White | Fire extinguishers, fire hydrants, fire blankets, fire alarms |

To ensure visibility in tough mining environments, durable materials like aluminium with Class 1 reflective properties are commonly used. These materials withstand harsh conditions, while UV-protective laminates prevent fading caused by exposure to sunlight, especially in open-pit mines. For temporary or movable signs, self-adhesive vinyl is a practical choice.

Mining sites often require custom solutions to meet specific needs. For example, signs can include tailored wording for designated muster points, specialised equipment locations, or increased sizes for visibility in large underground spaces. Companies like PXP Safety offer customised fire and emergency signs using UV-protected aluminium and other durable materials to ensure compliance and longevity. Standard emergency signs are available from approximately $8, while larger, reflective options range between $65 and $85 [2].

sbb-itb-9950c92

6. Regulatory and Traffic Signs

Regulatory and traffic signs play a vital role in managing vehicle and pedestrian movement while defining operational zones in mining environments. These signs are crucial for preventing collisions in tight spaces, guiding heavy machinery safely, and marking operational boundaries clearly. In Western Australia, signage requirements are governed by the Mines Safety and Inspection Act 1994 and the Mines Safety and Inspection Regulations 1995. Nationally, compliance with AS 1319-1994 for workplace safety signage and AS 1742.1 for speed limit signs is mandatory [1][3].

The main categories of regulatory signs – prohibition, mandatory, and restriction – help control site traffic and define operational areas. Restriction signs, for example, feature a red circle without a slash to indicate specific limits, such as speed restrictions in high-traffic zones [1][6]. These categories guide the choice of materials to ensure signs remain visible and durable under harsh conditions.

Using durable materials is essential for creating long-lasting signage in mining environments. Aluminium is a popular choice as it withstands moisture, dust, and chemicals, while UV-protective laminates prevent fading, maintaining visibility even in challenging conditions like underground mines or night shifts. For these environments, Class 1 or Class 100 reflective vinyl is recommended, as it ensures visibility when illuminated by vehicle headlights [3][6]. In well-lit areas, symbols should measure at least 15 mm per metre of viewing distance, with a 50% size increase for poorly lit conditions [1].

Proper placement is equally important. Signs should be positioned within an observer’s line of sight and set against contrasting backgrounds to avoid being obscured by equipment or materials [1]. Regular maintenance is crucial – faded or damaged signs must be replaced promptly to maintain safety and compliance [3]. For confined spaces or areas with high hazards, signs should be at least 600 mm × 450 mm to ensure high visibility [7].

Customised solutions can further improve safety in mining operations. Site-specific needs might include unique vehicle identification numbers, tailored instructions, or larger signs for expansive underground areas. Companies like PXP Safety offer customised regulatory and traffic signs made from UV-protected aluminium with outdoor-grade printing, providing durable and compliant signage tailored to mining applications [2].

7. Direction and Wayfinding Signs

Direction and wayfinding signs play a vital role in guiding vehicles and personnel across mining sites, whether underground or on the surface. These signs help manage traffic flow to avoid collisions in confined areas, outline safe pedestrian pathways, and designate specific activity zones. In emergencies, they serve a critical purpose by marking evacuation routes and muster points. By providing clear and concise navigational instructions, these signs work hand-in-hand with other safety signage to maintain order and safety.

In Australia, mining operations must adhere to AS 1319-1994 and relevant state regulations. Just as hazard and emergency signs contribute to workplace safety, well-designed wayfinding signs ensure smooth and efficient navigation. Emergency information signs are typically green with white text or symbols, while general information signs often feature white or blue to indicate facilities or operational details [1].

For these signs to withstand the harsh conditions of mining environments, material choice is key. Durable materials like aluminium with UV-protective laminates and reflective vinyl are commonly used to ensure both longevity and visibility. To maximise effectiveness, signs should be mounted at eye level and placed against contrasting backgrounds to remain clear and unobstructed by equipment or other site materials.

Customisation is another important aspect of wayfinding signage. While adhering to standard safety designs, signs can be tailored to meet the specific needs of a site. For example, mining operations often require signs that indicate unique UHF communication channels, identify muster points by name, or incorporate company branding – all while complying with Australian Standards. Companies like PXP Safety specialise in creating customised direction and wayfinding signs made from UV-protected aluminium with outdoor-grade printing, ensuring durable and site-specific solutions for the mining industry.

Regular upkeep is essential to maintain the effectiveness of these signs. Faded or damaged signs should be promptly replaced to ensure safety standards and compliance are upheld.

8. Custom Signs for Mining Operations

Custom signage goes beyond standard designs to tackle the unique challenges present in mining environments. These signs are tailored to address specific hazards, such as unstable ground conditions, machinery configurations, and site-specific traffic management. They can also include company branding or logos, helping to establish clear site ownership while maintaining a professional look across extensive operations.

It’s important that custom signs meet AS1319-1994 standards and adhere to relevant state regulations [1][3]. For vehicles and machinery, signage often needs to comply with MDG 15 standards [8]. Interestingly, AS1319 doesn’t impose strict requirements on materials or sizes, allowing flexibility in choosing materials that best suit the site’s needs [1].

One of the biggest advantages of custom signs is their durability in harsh mining conditions. These signs are designed to resist UV exposure, moisture, dust, chemicals, and even high-pressure washdowns. In fact, patented high-visibility mining signs have been shown to last up to four years in extreme environments and are completely resistant to water cannon cleaning [8]. This long-lasting durability not only reduces replacement costs but also minimises downtime caused by faded or damaged signs, ensuring operations continue smoothly [8]. Beyond their resilience, customisation options allow these signs to meet specific operational demands.

Customisation isn’t limited to text changes. Mining sites can request unique shapes through digital cutting, sizes tailored to specific post sleeves, varied mounting options, and specialised materials like UV-protected aluminium with outdoor-grade printing. These signs can also display critical information such as entry requirements, PPE instructions, multi-message layouts, or machinery "call up" notifications [9]. For instance, PXP Safety offers custom sign solutions with aluminium bases, solvent outdoor printing, and UV protective film – all designed to meet Australian safety standards and the specific needs of your operation. When combined with standard signage, these custom solutions form a comprehensive safety system for mining sites.

Manufacturers like PXP Safety can produce compliant custom signs within 3–5 days of artwork approval [9], ensuring your site stays up to code without unnecessary delays.

Why Compliance and Durability Matter in Mining Signage

Meeting Australian safety standards is not just best practice – it’s a legal requirement under the Mines Safety and Inspection Act 1994 and the Mines Safety and Inspection Regulations 1995 [3]. Adhering to AS1319-1994 ensures uniform safety signage across mining sites, safeguarding workers while helping companies avoid costly Work Health and Safety (WHS) fines [5].

But compliance is only part of the story. Clear, properly sized signage is critical for quickly identifying hazards. Australian visibility standards mandate that symbols and text are scaled according to ambient lighting, with a 50% increase in size required for low-light conditions [1]. However, even the most visible signs lose their effectiveness if they can’t withstand the harsh realities of mining environments. Signs in these settings must endure intense UV exposure, dust, moisture, chemical splashes, and high-pressure washdowns.

"Fading and damaged hi‐visibility signage is a costly OH&S problem you don’t need."

This is why the materials used in signage are so important. High-visibility mining signs, when made from durable materials, can last up to four years in extreme conditions [8]. For example, PXP Safety produces signs using aluminium bases, solvent outdoor printing, and UV-protective film. These features not only meet Australian safety standards but also ensure the signs stand up to challenging environments.

Even the best signs require regular maintenance to remain effective. Routine inspections and prompt replacement of damaged signs are essential [3]. Placement also plays a key role – signs should be mounted at eye level, against contrasting backgrounds, and within the line of sight to remain noticeable despite nearby machinery or materials [1][3].

"The difference between safety and tragedy can hinge on the clarity and visibility of an emergency sign."

- Corsign [3]

When compliance is paired with durable, high-quality materials, signage performs reliably over time. This not only reduces replacement costs but also saves lives. Investing in robust signage – featuring aluminium construction, UV protection, and outdoor-grade printing – pays off in the long run. Standard signs typically range from $8 to $15, while larger-scale options are priced around $85 [2].

Conclusion

Mining safety signs are far more than just regulatory formalities – they are essential for protecting lives, ensuring smooth operations, and maintaining compliance within Australia’s mining industry. Each type of sign, whether it’s a standard warning or a customised solution, plays a crucial role in fostering workplace safety.

These signs are indispensable in creating a secure and efficient environment. They alert miners to potential hazards, provide guidance during emergencies, and support daily operations. As Corsign highlights, they truly are the unsung heroes of the mining sector [3]. This underscores the importance of consistent, high-quality signage across all mining sites.

The effectiveness of a safety sign hinges on three main factors: compliance with AS1319-1994 standards, durability to withstand harsh mining conditions, and strategic placement. Mining environments demand signs that can endure extreme UV exposure, dust, moisture, and chemical splashes without losing their clarity. Using robust materials like aluminium with UV-protective coatings and outdoor-grade printing ensures long-lasting performance. With standard signs costing between $8 and $15, and heavy-duty options around $85, the investment is minimal compared to the potential consequences of fines, operational delays, or, most importantly, risks to human life [2].

To maintain a safe mining operation, it’s vital to focus on regular inspections, timely replacement of worn or damaged signs, and customised solutions for specific site needs. Adhering to AS1319-1994 standards and ensuring durable installations are key to protecting both workers and operations. When properly maintained and strategically placed, the right signage contributes to a culture of safety that benefits everyone on site.

For signage solutions that meet the demands of Australia’s mining environments, PXP Safety offers a wide range of durable and compliant options designed to stand up to the toughest conditions in the industry.

FAQs

What are the most durable materials for mining safety signs?

When it comes to mining safety signs, aluminium and Colorbond-coated steel are top choices for durability. These materials are built to handle tough outdoor conditions, such as intense UV rays, extreme heat or cold, and heavy usage.

Aluminium stands out for being lightweight and resistant to corrosion, making it perfect for long-term applications. On the other hand, Colorbond-coated steel is known for its strength and resilience. Both materials ensure safety signs stay clear and reliable, even in the harshest mining environments.

How do custom mining safety signs comply with Australian standards?

Custom mining safety signs are designed to meet the requirements of AS 1319-1994, ensuring they follow precise rules for classification, colour and shape coding, text and symbol sizing, and material selection. These standards guarantee that the signs remain clear, long-lasting, and effective, even in the tough conditions typical of mining sites.

For instance, approved materials like retro-reflective or self-luminous surfaces are often used to ensure visibility in low-light or harsh environments. Additionally, the construction and installation methods are carefully chosen to maintain both readability and durability over time. Adhering to these standards is not just about compliance – it plays a vital role in creating a safer workplace for everyone.

Why is it important to regularly maintain mining safety signs?

Regular upkeep of mining safety signs is essential to keep them clear, visible, and functional, especially in Australia’s tough mining conditions, where dust, UV exposure, and extreme weather can take a toll. Signs that are faded, damaged, or dirty risk failing to communicate vital warnings or instructions, heightening the chance of accidents and undermining workplace safety.

It’s not just about safety – it’s the law. According to Australian Standard AS 1319, safety signs must remain legible and operational at all times. Routine cleaning, inspections, and prompt repairs are key to meeting these requirements. This approach also helps extend the lifespan of high-quality signs, like PXP Safety’s aluminium signs with UV protection, saving money by avoiding frequent replacements.

By adopting a proactive maintenance program, companies can reinforce a strong safety culture, reduce downtime, and provide workers with dependable visual guidance to manage hazards effectively.

Related Blog Posts

You may also be interested in

Safety Sign Colour Guide

Discover the meanings of safety sign colours in Australia with our easy guide. Learn what red, yellow, green, and blue signs mean instantly!

Common Safety Signage Issues and Fixes

Poorly placed, faded or non-compliant safety signs put workers and businesses at risk; this guide explains common issues and practical WHS fixes.

Checklist: Safety Signs for Policy Integration

Audit, update and maintain AS 1319-compliant workplace safety signs: map hazards, assign ownership and schedule inspections for WHS compliance.

Exit Signs vs. Evacuation Route Signs: Key Differences

Compare exit signs and evacuation route diagrams: roles, placement and Australian standards (AS/NZS 2293, AS 3745) for safe transport facilities.

Vehicle Entry Signs for Warehouses

Vehicle entry signs are the frontline defence in Australian warehouses, enforcing AS 1319, separating pedestrians and vehicles to prevent collisions.