PPE Signs Australia: Types and Uses

PPE signs are more than just symbols – they’re legally required tools for workplace safety in Australia. They guide workers to wear protective gear, reducing accidents and ensuring compliance with Work Health and Safety (WHS) laws. These signs, defined by the AS 1319:1994 standard, use blue circles with white pictograms to indicate mandatory safety measures.

Here’s what you need to know:

- Purpose: PPE signs minimise risks in high-hazard industries like construction, transport, and manufacturing.

- Legal Requirements: Employers must install these signs in relevant areas to avoid penalties of up to $3 million for corporations.

- Design Standards: Signs must follow AS 1319:1994, ensuring visibility and clarity with specific size, colour, and placement guidelines.

- Types: Common signs include hard hat, eye protection, hearing protection, gloves, and respiratory gear requirements.

- Placement: Signs should be at eye level, well-lit, and unobstructed, especially in high-risk zones.

- Durability: Use materials like UV-protected aluminium or polypropylene to withstand Australia’s harsh climate.

PPE signs are essential for safety compliance and protecting workers from harm. Regular inspections, proper placement, and durable materials ensure they remain effective.

Safety Signs in Australia

PPE Signs and Australian Standards

PPE signs and Australian Standards are essential for workplace safety, ensuring legal requirements are met while fostering a strong safety culture.

What Are PPE Signs?

PPE signs indicate the mandatory use of specific protective equipment, featuring blue circular backgrounds with white pictograms. These signs are enforceable under Australian Work Health and Safety (WHS) laws and are commonly used in high-risk industries such as construction, manufacturing, and transport [1].

By clearly identifying hazards and the required protective measures, these signs help minimise the risk of accidents, especially in environments where PPE is critical for worker safety [1].

Understanding the purpose of PPE signs is key to appreciating the detailed standards that guide their design and use.

Australian Standards for PPE Signs

PPE signs must adhere to the guidelines outlined in AS 1319:1994, which establishes strict design requirements to ensure they are easily recognisable and effective in communicating hazards. The primary aim of this standard is to regulate safety behaviours, warn about hazards, and provide emergency instructions in a clear and immediate way.

Mandatory signs are required to display a white symbol within a blue disc, accompanied by black text on a white background [2]. To ensure visibility, the symbols must be at least 15 millimetres per metre of viewing distance. Additionally, uppercase text should measure at least 5 millimetres per metre in well-lit areas, with these dimensions increased by at least 50% in poorly lit conditions. Signs must also be installed at eye level on a surface that contrasts with the background and remains unobstructed.

While compliance with AS 1319:1994 is not legally mandatory, following its guidelines is essential for meeting WHS obligations. Safe Work Australia oversees these requirements, with enforcement managed by state and territory bodies such as WorkSafe Victoria, SafeWork NSW, and WorkSafe ACT [3]. Courts may also evaluate whether signs meet AS 1319 standards when assessing whether a duty holder has fulfilled their WHS responsibilities [4].

Types of PPE Signs and Their Uses

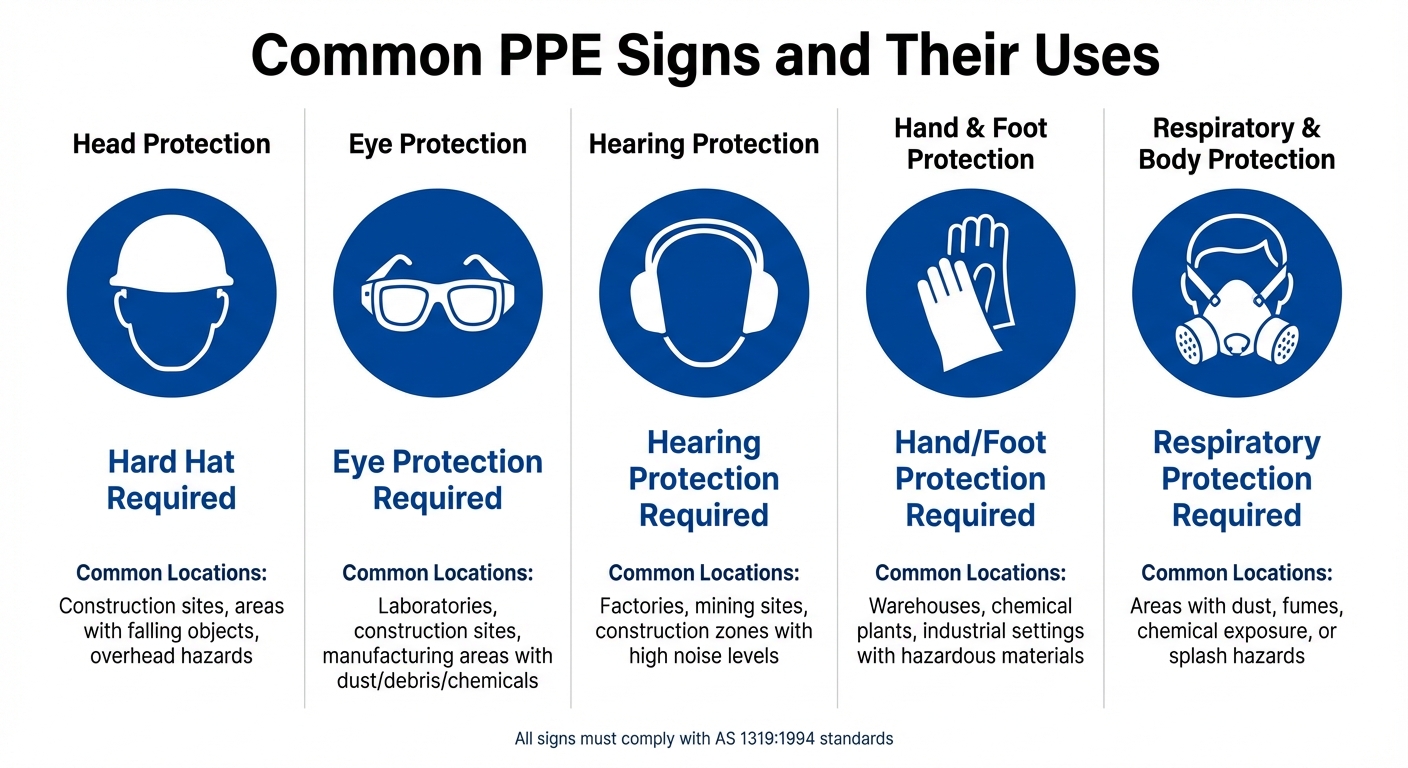

Common PPE Sign Types and Their Workplace Applications in Australia

In Australian workplaces, PPE signs are generally categorised as mandatory signs. These signs use clear pictograms designed for instant recognition, ensuring all workers – regardless of language or literacy – can understand the required safety measures. This is especially important in Australia’s diverse workforce.

Here’s a breakdown of common PPE signs and where they’re typically used:

Head Protection Signs

"Hard hat required" signs are marked by a white hard hat symbol inside a blue circle. These signs signal that head protection is a must, often found on construction sites or areas where falling objects or overhead hazards pose a threat.

Eye Protection Signs

"Eye protection required" signs feature a white safety glasses symbol within a blue circle. These signs are essential in workplaces like laboratories, construction sites, and manufacturing areas, where dust, debris, or chemicals can endanger workers’ eyes.

Hearing Protection Signs

Hearing protection signs, showing a white earmuffs symbol in a blue circle, indicate that earplugs or earmuffs must be worn in noisy environments. These signs are commonly found in factories, mining sites, and construction zones to help prevent hearing damage.

Hand and Foot Protection Signs

Hand protection signs display a white glove symbol inside a blue circle, requiring gloves in areas where workers handle hazardous materials or heavy objects. Foot protection, often indicated by general PPE signage, mandates safety boots. These signs are frequently seen in warehouses, chemical plants, and industrial settings.

Respiratory and Body Protection Signs

Respiratory protection signs call for masks or respirators in areas with risks such as dust, fumes, or chemical exposure. Similarly, body protection signs signal the need for coveralls or aprons to shield against chemical splashes or other hazards, ensuring workers stay protected in high-risk environments.

sbb-itb-9950c92

Where to Place and Install PPE Signs

Where to Place PPE Signs

The right placement of PPE signs not only ensures compliance with safety regulations but also reinforces awareness in the workplace. Signs should be positioned where workers are most likely to encounter hazards – such as at entrances to risky areas or near PPE storage locations. Key spots include entry points to hazard zones, change rooms, and workstations with specific risks. For example, place eye protection signs near benches or workstation entrances, while foot protection signs are ideal for warehouse loading bays or building entry points.

"A mandatory safety sign isn’t doing its job unless it’s impossible to miss." – newsigns.com.au [1]

To maximise visibility, mount signs at eye level in well-lit, uncluttered areas. Using a contrasting background can make them stand out further. In areas with multiple PPE requirements, grouping related signs together improves clarity and reduces confusion. Ensure signs are securely fixed to prevent obstruction or damage.

According to AS 1319:1994, the size of pictograms and text must be scaled to the viewing distance – 15 mm per metre for pictograms and 5 mm per metre for uppercase text. These dimensions should be increased by 50% in poorly lit areas, ensuring compliance with Australian Standards and maintaining visibility.

Lastly, selecting robust materials is critical to ensure signs can endure Australia’s challenging environmental conditions.

Materials and Weather Resistance

Australia’s climate can be unforgiving, so PPE signs must be built to last. Outdoor signs need to resist harsh UV rays and extreme temperatures ranging from –40°C to 150°C. Aluminium signs with UV protection are a great choice, offering corrosion resistance and a lifespan of 5 to 8 years, making them suitable for construction sites, mining areas, and industrial yards. Polypropylene signs, UV stable and 1.4 mm thick, resist cracking and fading, lasting between 3 and 5 years.

For indoor environments, vinyl self-adhesive signs are an excellent option. They adhere well to walls, doors, and machinery, withstanding temperatures from –40°C to 80°C and lasting 5 to 8 years. Temporary construction sites often use flute signs made of 3 mm corrugated plastic. These are lightweight, cost-effective, and flexible enough to attach to curved surfaces like fences and gates.

Worn or obscured signs should be replaced without delay. Faded or damaged signage not only fails to communicate effectively but also increases the risk of workplace injuries and breaches of safety regulations.

Custom PPE Signs and Legal Requirements

Custom PPE Signs

Custom PPE signs go beyond the basics of standard signage to address specific workplace hazards. They are particularly useful when standard signs don’t cover risks posed by unique machinery, unusual chemical exposures, or other site-specific dangers. To be effective and easily recognisable, these signs must comply with the AS 1319-1994 standards.

Start by conducting a thorough risk assessment to pinpoint hazards and determine the necessary PPE. Work with a trusted provider familiar with AS 1319-1994 to create signs that align with both safety and operational needs. Choosing the right materials is equally important. For tough outdoor settings like mine sites, vinyl with UV laminate offers long-lasting durability. Meanwhile, self-adhesive vinyl works well for indoor spaces. The design should also prioritise clarity – text and symbols must be easy to read, and in low-light conditions, sizes should be increased by at least 50% to maintain visibility.

"A sign that’s blocked, faded, or too small is as good as no sign at all." – Reflective Fabrications

Legal Requirements for PPE Signage

Under the Work Health and Safety Act 2011 and its regulations, employers (or Persons Conducting a Business or Undertaking) are legally required to provide adequate safety signage. This is crucial for safeguarding both workers and visitors from potential hazards. Signs must be strategically placed in areas where risks are present and kept in good condition through regular inspections and maintenance.

Custom PPE signs play a vital role in ensuring compliance with workplace safety laws. They should be part of a comprehensive safety system that includes regular risk assessments, employee training, and ongoing safety management. Adhering to AS 1319-1994 is non-negotiable. Collaborating with an experienced provider, such as PXP Safety, can help you design and install signage that meets legal standards while addressing the specific needs of your workplace.

Conclusion

PPE signs aren’t just a legal box to tick – they’re essential for preventing workplace injuries. These signs convey critical safety measures and help shield workers and visitors from potential hazards. Following AS 1319-1994 ensures signage is clear, easily visible, and understandable to everyone on site, regardless of language or literacy skills.

Compliance aside, investing in durable signage is vital for long-term safety under Australian WHS laws. High-quality signs made from materials like aluminium, with UV protection and outdoor-grade printing, can withstand Australia’s tough weather conditions while remaining legible. This demonstrates your commitment to managing risks – a key factor in defending against workplace claims.

To keep PPE signs effective, they must be clearly visible and in good condition. Regular inspections and prompt replacements are essential to ensure they continue to deliver important safety messages to all workers and visitors.

Both standard and customised PPE signs are crucial for meeting Australian safety standards. Proper placement, routine checks, and using weather-resistant materials are key to staying compliant and protecting everyone on site. PXP Safety offers signage designed specifically for Australian workplaces, using robust aluminium with UV protection to handle harsh conditions. Their custom sign service also ensures unique site hazards are addressed while adhering to AS 1319-1994.

Integrating PPE signage into your workplace safety system is a must. Combine quality signage with strategic placement, regular maintenance, and thorough worker training to build a safer work environment that meets your legal responsibilities and protects everyone on site.

FAQs

What happens if PPE signage standards are not followed in Australia?

Failing to follow PPE signage standards in Australia can lead to serious legal repercussions, including hefty fines and regulatory penalties under the Work Health and Safety (WHS) laws. These signs play a crucial role in identifying hazards, outlining safety procedures, and adhering to Australian Standards like AS 1319.

Beyond the legal risks, neglecting proper signage significantly raises the chances of workplace accidents, which can harm both employees and business operations. It can also tarnish a company’s reputation and cause costly disruptions. Ensuring your signage meets the required standards is a key step in creating a safe and compliant workplace.

What steps can businesses take to keep their PPE signs effective and visible in Australia’s challenging weather conditions?

To keep PPE signs functional and easy to spot in Australia’s challenging weather conditions, it’s important to select long-lasting materials like aluminium paired with UV-resistant coatings and outdoor-grade printing. These choices help protect signs from fading, corrosion, and weather-related damage.

Positioning also plays a big role in ensuring visibility. Install signs at eye level in areas that are well-lit and free from obstructions. Adding reflective or illuminated elements can make a big difference in low-light or poor weather conditions. Don’t forget regular upkeep – cleaning and checking for wear and tear will keep your signs clear, legible, and up to standard.

Why is it crucial to customise PPE signs for specific workplace hazards?

Customising PPE signs plays a key role in addressing the specific risks unique to your workplace. These tailored signs are designed to clearly highlight particular hazards, instruct workers on the appropriate PPE to wear, and ensure compliance with Australian safety standards.

When you opt for customised signage, you create a safer workplace by reducing misunderstandings and making safety measures crystal clear. This approach not only minimises confusion but also helps everyone stay informed about the necessary precautions for various tasks or areas, contributing to a safer and smoother workflow.

Related Blog Posts

You may also be interested in

Safety Sign Colour Guide

Discover the meanings of safety sign colours in Australia with our easy guide. Learn what red, yellow, green, and blue signs mean instantly!

Common Safety Signage Issues and Fixes

Poorly placed, faded or non-compliant safety signs put workers and businesses at risk; this guide explains common issues and practical WHS fixes.

Checklist: Safety Signs for Policy Integration

Audit, update and maintain AS 1319-compliant workplace safety signs: map hazards, assign ownership and schedule inspections for WHS compliance.

Exit Signs vs. Evacuation Route Signs: Key Differences

Compare exit signs and evacuation route diagrams: roles, placement and Australian standards (AS/NZS 2293, AS 3745) for safe transport facilities.

Vehicle Entry Signs for Warehouses

Vehicle entry signs are the frontline defence in Australian warehouses, enforcing AS 1319, separating pedestrians and vehicles to prevent collisions.