PPE Mandatory Signs for Warehouses

PPE mandatory signs in Australian warehouses aren’t optional – they’re required by law. These signs ensure worker safety by clearly indicating when hard hats, safety boots, high-visibility clothing, or other protective gear must be worn. They are designed to reduce workplace accidents, especially in high-risk areas like loading docks or zones with moving machinery.

Here’s what you need to know:

- Legal Obligation: Compliance with Work Health and Safety laws and AS 1319-1994 standards is mandatory.

- Key Hazards Addressed: Risks include falling objects, moving vehicles, and hazardous materials.

- Types of PPE Signs: Common examples include head protection, foot protection, and high-visibility clothing signs.

- Placement: Signs should be positioned at entry points to hazardous zones, at eye level, and in well-lit areas.

- Maintenance: Regular inspections are critical to ensure signs remain visible and effective.

- Worker Training: Employees must understand and follow signage instructions to maintain a safe workplace.

PPE signs are essential for protecting workers in dynamic and potentially dangerous warehouse environments. They serve as constant reminders of safety requirements, helping to prevent injuries and ensure compliance with Australian safety standards.

PPE Safety | Warehouse Safety Tips

Why Warehouses Need PPE Mandatory Signs

Warehouses are bustling hubs of activity, but they also come with their fair share of risks. From heavy machinery to manual handling, the potential for accidents is ever-present. This is where PPE mandatory signs come into play. These signs act as clear visual reminders, warning workers and visitors about hazards and ensuring everyone follows safety protocols. Whether it’s a zone with overhead risks or an area with moving forklifts, well-placed signs prompt immediate action, offering vital guidance in a fast-paced and potentially hazardous environment.

Common Warehouse Hazards

Warehouses are full of potential dangers, making PPE mandatory signs an essential safety measure. Moving machinery like forklifts, pallet jacks, and scissor lifts pose collision and crushing risks. Signs reminding workers to wear high-visibility clothing and steel-capped boots can help minimise these dangers. Overhead hazards from stacked goods on high shelves highlight the need for head protection signs. Meanwhile, routine manual handling increases the likelihood of musculoskeletal injuries, and areas storing hazardous materials require clear warnings about the specific PPE needed. In noisy zones, signs stating "Hearing and eye protection must be worn" ensure workers are aware of the additional safety gear required.

Beyond mitigating these risks, Australian workplace safety laws make PPE signage a mandatory aspect of maintaining a safe working environment.

Legal Requirements

In Australia, PPE signage isn’t just a good idea – it’s the law. Work Safe Australia enforces specific guidelines for safety signs under the Code of Practice AS 1319:1994 [6]. According to these regulations, a Person Conducting a Business or Undertaking (PCBU) must display appropriate signage to indicate PPE requirements [5]. Failing to comply can result in hefty penalties from regulatory authorities [4]. Employers are responsible for evaluating workplace hazards, choosing the right PPE, providing employee training, and ensuring the equipment fits properly [7]. PPE mandatory signs act as a constant visual cue, reinforcing training and ensuring compliance with these legal standards.

Types of PPE Mandatory Signs for Warehouses

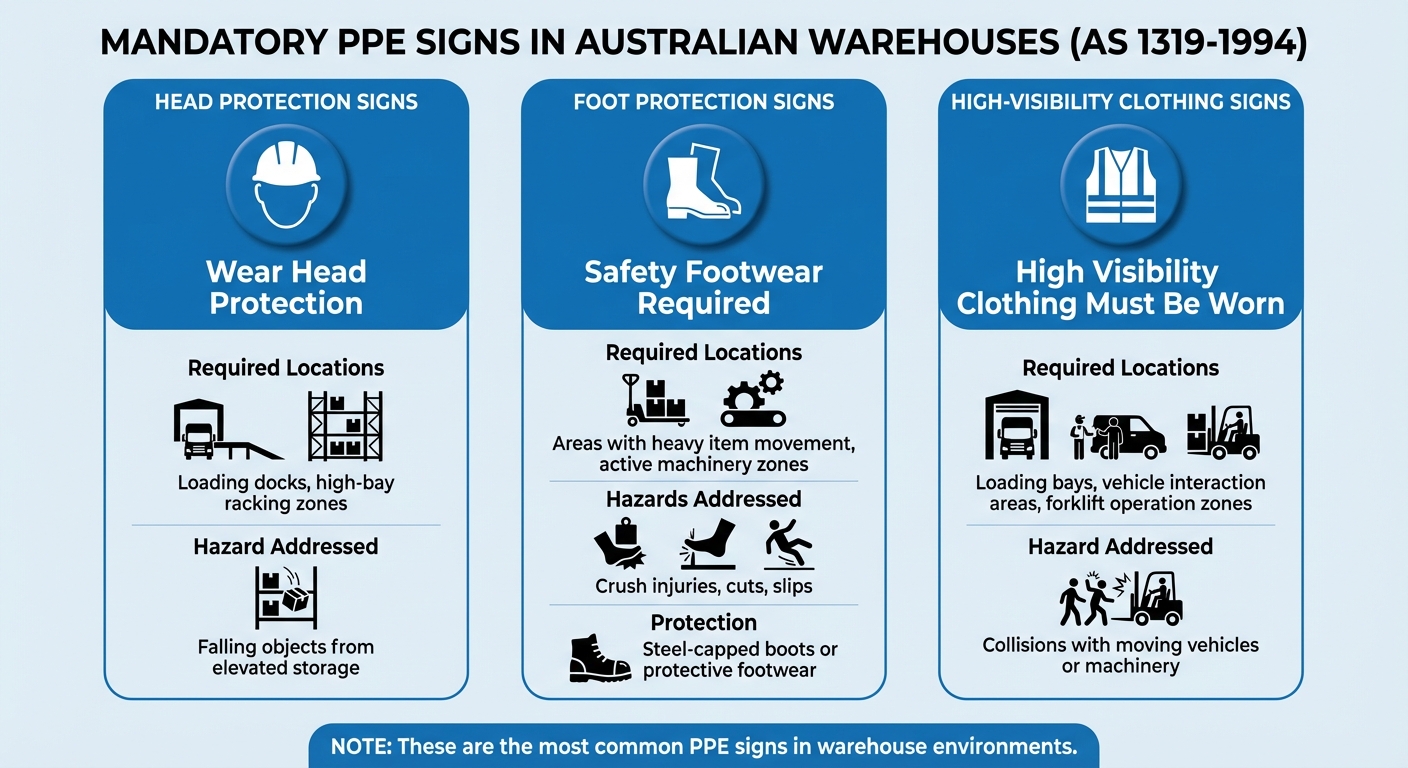

Types of PPE Mandatory Signs Required in Australian Warehouses

In Australian warehouses, PPE mandatory signs play a crucial role in minimising risks and ensuring worker safety. Designed according to AS 1319-1994 standards, these signs feature a white symbol on a blue disc and clearly communicate instructions that must be followed, often using the word "MUST" in their directives [8].

The types of signs required in a warehouse depend on the specific hazards present in each area. Among the most common are those addressing head protection, foot protection, and high-visibility clothing – three areas where injuries are most likely in warehouse environments. Let’s take a closer look at these essential signs.

Head Protection Signs

Areas with a risk of falling objects, such as loading docks and high-bay racking zones, require "Wear Head Protection" signs. These signs remind workers to wear hard hats to guard against injuries caused by items dislodging from elevated storage [2]. The white hard hat symbol on a blue disc serves as an immediate visual cue for all personnel to comply [8]. Without head protection, workers in these zones face serious injury risks.

Foot Protection Signs

In operational zones where heavy items are moved or machinery is active, "Safety Footwear Required" signs are indispensable. These signs ensure workers wear steel-capped boots or other protective footwear to shield against crush injuries, cuts, and slips [2]. The white safety boot symbol on a blue background delivers a clear message [8]. Areas with pallet movement, sharp debris, or rolling equipment are particularly hazardous without proper foot protection.

High-Visibility Clothing Signs

To reduce the risk of accidents involving moving vehicles or machinery, "High Visibility Clothing Must Be Worn" signs are essential. These signs are typically displayed in loading bays, vehicle interaction areas, and zones where forklifts or other equipment operate [2]. The white high-vis vest symbol on a blue disc ensures workers are easily seen by operators, reducing the chance of collisions [8]. High-visibility clothing is a simple yet effective measure to enhance safety in busy, high-risk areas.

How to Place and Install PPE Signs

Getting the placement right is what separates effective PPE signs from those that go unnoticed. Thoughtful positioning ensures your warehouse meets WHS laws and complies with AS 1319:1994 standards [4].

Where to Place Signs

Position signs at all entry points to hazardous zones, such as loading docks, confined spaces, or areas with specific risks. This ensures workers are alerted to potential dangers before entering. Signs should also be placed near equipment like welding bays, grinding stations, or chemical storage areas, as well as at every confined space entry point [3].

Install signs at chest or eye level for maximum visibility [4]. Make sure they’re well-lit and mounted against a contrasting background to stand out. Keep the surrounding area clear of obstructions. In poorly lit spaces, consider enlarging symbols to at least 15 mm per metre of viewing distance, and use uppercase text with a minimum size of 5 mm per metre [1].

It’s also a good idea to post signs near PPE storage areas and change rooms to remind workers of safety protocols.

By following these strategies, you can create a safety signage system that’s easy to notice and follow.

Combining PPE Signs with Other Safety Signage

Once you’ve optimised the placement of individual PPE signs, think about how they work alongside other safety signage. Pairing PPE signs with prohibition signs (red circles with diagonal lines) or warning signs (black symbols on yellow triangles) can provide a more complete picture of workplace risks and the actions required. Adding floor markings and directional signs can further guide workers by clearly marking pedestrian walkways and vehicle routes.

However, avoid overloading an area with too many signs. As ID Label Inc. advises:

When there are too many signs posted at one location, important information can get lost in translation. Ensure you have only enough warehouse signs and labels to convey safety information so it’s understood and retained by employees [10].

In safety signage, less is often more. Strategic placement and thoughtful integration are far more effective than overwhelming workers with excessive information.

sbb-itb-9950c92

Maintaining and Inspecting PPE Signage

Keeping PPE signage in good condition is crucial for compliance with AS 1319-1994 and ensuring workplace safety [11].

Regular Inspection and Maintenance

Once PPE signage is installed, regular upkeep is essential. Schedule routine workplace inspections to review all signage thoroughly. Check for any signs of wear, fading, corrosion, or damage that could compromise their visibility or effectiveness. It’s also important to keep signs clean, properly lit, and in good condition to meet compliance standards [11][12]. Damaged or faded signs lose their clarity and become non-compliant [3].

Customise inspection checklists to address specific hazards in your workplace, with input from health and safety representatives [12]. Beyond regular inspections, additional checks should be conducted following significant changes, such as new equipment installations, process updates, or workplace incidents [12]. Document all findings and address any issues promptly [12].

Persons Conducting a Business or Undertaking (PCBUs) are responsible for periodically evaluating the effectiveness of PPE signage [5][13]. This includes ensuring signs remain visible and are not blocked by materials or equipment [11]. For areas with poor lighting, consider increasing the size of signs by 50% to improve visibility [11].

Training Workers on PPE Signage

Workers are key to maintaining effective signage. Provide training to help them identify and report damaged, obscured, or missing signs [5][13]. Toolbox talks can be a great way to regularly reinforce the purpose of each PPE sign and highlight the importance of compliance for their safety.

Integrate PPE signage into your broader safety training programme. When workers understand the risks associated with each sign, they’re more likely to follow safety requirements and report issues. This not only helps maintain the effectiveness of your signage system but also ensures your warehouse stays compliant with WHS regulations [11]. By combining proactive maintenance with worker training, you can support a reliable and compliant PPE signage system that prioritises safety and clarity.

Choosing Quality PPE Mandatory Signs

Selecting the right PPE mandatory signs is crucial for ensuring safety and compliance in your warehouse. These signs should meet the requirements of AS1319-1994, which outlines design standards but doesn’t dictate specific materials or sizes [1]. This flexibility allows you to choose materials suited to your warehouse’s unique conditions without compromising on compliance.

What to Look for When Buying Signs

First and foremost, ensure that all signs comply with AS1319-1994 standards. Beyond compliance, durability is a key factor. For indoor environments, polypropylene signs are a solid choice, while metal signs are better suited for harsher conditions [14].

Clarity is equally important, especially in workplaces with a multilingual workforce. Opt for signs with clear, bold text and universally recognised icons. Standard sizes typically range from 225 mm x 300 mm to 900 mm x 600 mm, ensuring visibility from the required viewing distance [9]. These considerations help you create a safer and more tailored environment for your warehouse.

Custom PPE Signs for Your Warehouse

Sometimes, standard signs might not address every hazard in your workspace. Custom PPE signs give you the flexibility to address specific risks while staying compliant with AS1319-1994 [15]. You can combine multiple symbols – such as those for hard hats, high-visibility clothing, and safety footwear – and include location-specific captions like "on this site" or "in this area." Additionally, you can incorporate your company logo for a professional touch [15]. Starting at just $35.23 (excluding GST), custom PPE signs offer a cost-effective way to meet site-specific safety requirements [9].

PPE Signs from PXP Safety

PXP Safety offers PPE signs that go beyond compliance, focusing on durability and customisation. Their signs are built with a sturdy aluminium base, solvent outdoor printing, and a UV-protective film to withstand harsh conditions and prevent fading. Whether you’re after standard mandatory signs or customised solutions tailored to your warehouse’s unique hazards, PXP Safety provides reliable options that meet Australian standards while offering flexibility and long-lasting performance.

Conclusion

PPE mandatory signs play a key role in safeguarding workers, particularly in environments where other safety measures cannot completely eliminate risks. In Australian warehouses, these signs are vital for conveying critical safety messages and ensuring compliance with AS 1319-1994 standards. However, meeting these standards is about more than just ticking boxes – it’s about integrating safety into everyday operations [5][16].

Take a moment to assess whether your signage is doing its job effectively. Are the signs easy to spot? Do they address specific hazards? Are they in good condition? Faded, damaged, or outdated signs should be replaced immediately to maintain their effectiveness. But remember, evaluating your signage is just one piece of the puzzle in creating a safe workplace.

Signs alone aren’t enough to keep workers safe. PCBUs (Persons Conducting a Business or Undertaking) must ensure workers are properly trained and understand how to use PPE correctly. Regular training sessions and open communication can help address common issues like discomfort or confusion about when PPE is necessary [5][16].

FAQs

What are the risks of not displaying PPE mandatory signs in Australian warehouses?

Failing to display mandatory PPE signs in Australian warehouses can have severe repercussions. Businesses risk breaching Work Health and Safety (WHS) regulations, which can result in hefty fines or legal proceedings. Beyond the legal risks, the absence of these signs heightens the chances of workplace accidents, injuries, or even fatalities.

Proper signage isn’t just about ticking a compliance box – it plays a critical role in fostering a safer work environment. Clear signs help convey essential safety measures to both employees and visitors, reducing risks and promoting awareness.

How often should PPE mandatory signs in warehouses be checked and maintained?

PPE mandatory signs in warehouses need regular checks and upkeep to ensure they’re clear, readable, and meet Australian Standards (AS 1319). How often you inspect them should align with your workplace’s risk assessments. However, it’s a good practice to review them during routine safety audits or whenever there’s a change in the work environment.

Keeping these signs in good condition is especially important in areas prone to tough conditions like dust, moisture, or UV exposure. If signs become damaged or fade, replace them immediately to uphold safety and compliance standards.

Can PPE signs be tailored to highlight specific hazards in a warehouse?

Yes, PPE signs can be designed to address the unique hazards present in a warehouse environment. You can include customised text, symbols, or combinations that highlight specific requirements such as wearing safety glasses, hearing protection, respirators, hard hats, gloves, or safety boots.

This tailored approach ensures your signage meets Australian safety standards while addressing the specific risks of your workplace. Custom signs enhance clarity and help ensure workers are well-informed about the protective equipment needed for particular tasks or areas.

Related Blog Posts

You may also be interested in

Safety Sign Colour Guide

Discover the meanings of safety sign colours in Australia with our easy guide. Learn what red, yellow, green, and blue signs mean instantly!

Common Safety Signage Issues and Fixes

Poorly placed, faded or non-compliant safety signs put workers and businesses at risk; this guide explains common issues and practical WHS fixes.

Checklist: Safety Signs for Policy Integration

Audit, update and maintain AS 1319-compliant workplace safety signs: map hazards, assign ownership and schedule inspections for WHS compliance.

Exit Signs vs. Evacuation Route Signs: Key Differences

Compare exit signs and evacuation route diagrams: roles, placement and Australian standards (AS/NZS 2293, AS 3745) for safe transport facilities.

Vehicle Entry Signs for Warehouses

Vehicle entry signs are the frontline defence in Australian warehouses, enforcing AS 1319, separating pedestrians and vehicles to prevent collisions.