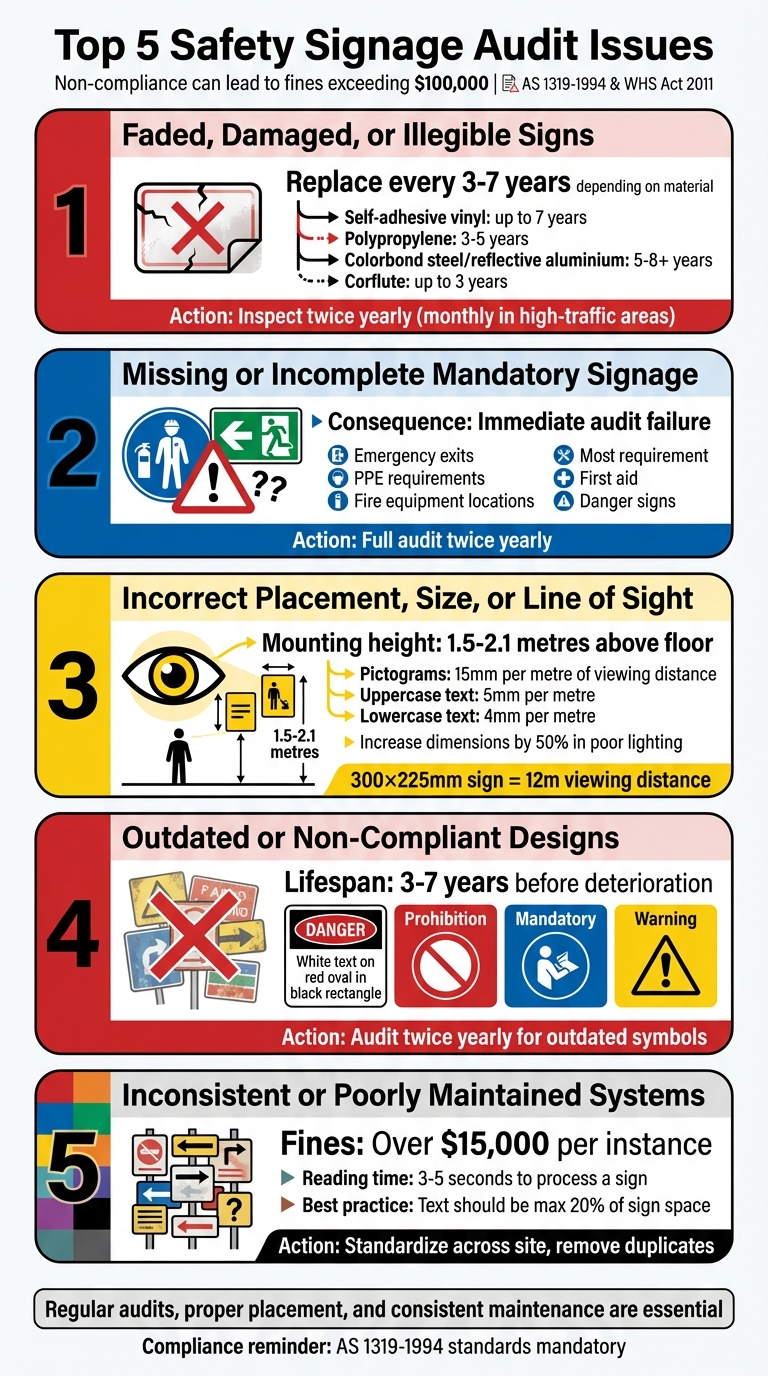

Top 5 Common Safety Signage Audit Issues

Safety signage audits are critical for ensuring compliance with Australian standards like AS 1319-1994 and the Work Health and Safety (WHS) Act 2011. Non-compliance can lead to fines exceeding $100,000, increased injury risks, and invalidated insurance claims. The five most frequent issues identified during audits are:

- Faded, damaged, or illegible signs: Australia’s harsh climate accelerates wear and tear. Signs must be inspected regularly, cleaned, and replaced every 3–7 years depending on material and exposure.

- Missing or incomplete mandatory signage: Key signs like emergency exits, PPE requirements, and fire equipment locations are often overlooked, leading to immediate audit failures.

- Incorrect placement, size, or line of sight: Signs must be mounted between 1.5–2.1 metres, sized for visibility, and positioned for clear, unobstructed viewing.

- Outdated or non-compliant designs: Signs must adhere to AS 1319-1994 standards for colours, symbols, and layouts. Faded or improvised designs are non-compliant.

- Inconsistent or poorly maintained systems: Mixed messaging or cluttered layouts confuse workers and fail audits. Regular maintenance and standardised designs are essential.

Regular audits, proper placement, and consistent maintenance are key to avoiding penalties and ensuring workplace safety.

Top 5 Safety Signage Audit Issues and Compliance Requirements

OSHA Safety Signs: Where Should Safety Signs Be Placed

1. Faded, Damaged, or Illegible Signs

Faded or damaged safety signs can seriously undermine workplace safety audits. When colours fade, vinyl starts peeling, or panels crack, the sign loses its ability to convey critical safety messages. Auditors often flag these signs as immediate risks since unreadable signs fail to warn workers about potential hazards [2].

Australia’s tough climate plays a big role in speeding up the wear and tear of signage. UV rays can break down colours and materials, while rain and high humidity lead to rust, corrosion, and grime accumulation. On top of that, daily site activities can further obstruct visibility. WorkSafe ACT emphasises:

For maximum effectiveness, safety signs should be maintained in good condition, kept clean and well illuminated [1].

Even the best-quality signs can deteriorate quickly without regular maintenance.

The choice of materials makes a significant difference in how long a sign lasts. Here’s a quick rundown:

- Self-adhesive vinyl: Suitable for outdoor use for up to 7 years.

- Polypropylene: Offers a lifespan of 3–5 years outdoors.

- Colorbond steel or reflective aluminium: Ideal for heavy-duty use, lasting 5–8+ years.

- Corflute: A temporary option effective for up to 3 years [7].

To stay ahead of wear and tear, inspect signage at least twice a year. For areas with heavy traffic or extreme weather, monthly checks are recommended. Clean signs using a soft cloth and mild detergent, and promptly replace any that show peeling, cracking, or fading.

Compliance with AS 1319-1994 is also essential. Symbols must be at least 15 mm per metre of viewing distance, and uppercase text should measure 5 mm per metre. In poor lighting, these dimensions should be increased by 50%. Signs should be mounted at a height of 1.5–2.1 m and positioned for clear, unobstructed visibility [1][8]. Tackling these issues early ensures a safer environment and sets the foundation for addressing other signage audit challenges.

2. Missing or Incomplete Mandatory Signage

Failing to display the correct mandatory signage is one of the most common reasons workplaces fail audits. According to Work Health and Safety (WHS) regulations, Australian workplaces are required to post specific signs wherever hazards, personal protective equipment (PPE) requirements, or emergency information is relevant [9]. The type of signage needed will vary depending on the hazards and operations at your workplace, but there are several key categories that apply universally.

These include signs for emergency exits, which must be clearly marked in every building, and fire equipment signs, which should be placed near extinguishers and fire blankets. First aid signs are necessary to indicate the location of medical kits or first aid rooms. Additionally, PPE signage is required in areas where protective gear – such as helmets, safety glasses, or high-visibility clothing – is mandatory. In high-risk areas, such as those with high voltage, confined spaces, forklifts, or hazardous chemicals, danger signs are essential.

Even something as simple as a missing ‘PPE Required’ or ‘Emergency Exit’ sign can lead to immediate audit failure and expose your business to significant legal risks.

Incomplete signage is a direct violation of WHS regulations. Non-compliance can result in fines, penalties, and increased liability, especially if an injury occurs. It is the responsibility of business owners and WHS officers to ensure all signage complies with AS 1319-1994 and Safe Work Australia standards. Under the model WHS Act, breaches are classified into three offence categories. The most serious, Category 1 offences, involve reckless conduct that puts someone at risk of death or serious injury, and these carry severe penalties [10]. Beyond financial consequences, failing to maintain proper signage undermines workplace safety culture. Regular reviews are crucial to ensure your signage meets current safety standards.

To address gaps, it’s recommended to perform a full signage audit at least twice a year or whenever there are changes to your workplace layout or operations [4]. Developing a site map that highlights every area needing safety or instructional signs can help ensure no spots are overlooked. During inspections, confirm that fire extinguisher signs are mounted 2 metres above the ground and that all mandatory signage is clearly visible and well-maintained [3].

3. Incorrect Placement, Size, or Line of Sight

Even when signs meet all technical requirements, they can still fail an audit if they’re placed poorly, sized incorrectly, or hidden from view. According to AS 1319-1994, signs should be mounted as close as possible to the observer’s vertical line of sight, typically between 1.5 metres and 2.1 metres above the floor [4].

This highlights just how crucial proper placement is for a sign to be effective.

"A sign that can’t be seen is a sign that doesn’t work. Signs hidden behind machinery, mounted too high, or angled poorly won’t pass inspection." – Phoenix Graphics [2]

The size of a sign isn’t random – it depends on factors like viewing distance, lighting, and the environment. AS 1319 specifies that pictograms should measure 15mm per metre of viewing distance, with uppercase text at 5mm and lowercase text at 4mm [11]. For instance, a standard Danger sign measuring 300×225mm works for a viewing distance of 12 metres. But if the distance increases to 18 metres, the sign should be upgraded to at least 450×300mm [12]. In dim lighting or dusty conditions, these dimensions should be increased by 50% to ensure readability [13].

Placement errors are common and include mounting signs on doors or windows (which can shift out of view), placing them where they might be obscured by stacked materials or equipment, or not ensuring they contrast with the background [13]. In areas with vehicle or forklift traffic, signs need to be larger because operators moving at speed can’t easily read smaller text or symbols compared to workers on foot [12].

To prevent these issues, conduct a field test: stand in the position where workers will typically view the sign and check if it’s legible without straining your eyes [11]. Signs should be perpendicular to the observer’s line of sight and mounted on a background that contrasts well [1]. Keep in mind that any changes to the layout of the space can create new obstructions [4].

sbb-itb-9950c92

4. Outdated or Non-Compliant Sign Designs

Safety standards aren’t static – they evolve over time. Signs that once met the required guidelines may no longer comply with current regulations. In Australia, the AS 1319-1994 Standard sets the benchmark for safety signage, replacing older standards with specific rules for layouts, symbols, and colours. Signs featuring outdated graphics, makeshift designs, or even home-printed versions often fail audits, making compliance a critical priority.

Each category of safety sign must follow strict design rules. For instance:

- Danger signs: Must display "DANGER" in white text on a red oval, enclosed by a black rectangle.

- Prohibition signs: Require a red circle with a diagonal slash over a black pictograph on a white background.

- Mandatory signs: Feature a blue circle with a white pictograph.

- Warning signs: Should use a yellow triangle with a black outline and pictograph.

Even if a sign’s message is clear, it will still be deemed non-compliant if it doesn’t adhere to these specific shapes, colours, and layouts.

The standard also outlines minimum luminance factors to ensure visibility under various lighting conditions. For example, yellow needs a minimum luminance factor of 0.45, green 0.12, red 0.07, and blue 0.05. Signs that have faded due to prolonged exposure to sunlight or harsh weather conditions will likely fall below these thresholds. Typically, safety signs have a lifespan of 3 to 7 years before they start to deteriorate and lose compliance [2].

To stay on top of this, conduct a signage audit twice a year to identify outdated symbols or non-standard designs. Replace any signs that fail to meet the AS 1319-1994 guidelines, particularly those with incorrect colour schemes or improvised graphics. When sourcing replacements, ensure they meet the standard’s chromaticity and size requirements. For instance, symbols should measure at least 15 mm per metre of viewing distance, and uppercase text must be no smaller than 5 mm per metre [1][7]. Companies like PXP Safety offer durable, compliant signage solutions that can be customised to meet these exact specifications.

5. Inconsistent or Poorly Maintained Signage Systems

When signage is inconsistent, poorly maintained, or sends mixed messages, it can cause confusion and lead to compliance issues. Imagine one sign requiring PPE while another nearby omits that instruction – workers might not know which to follow. Auditors see these inconsistencies as major red flags, and the resulting violations can lead to fines exceeding $15,000 per instance [2][15]. Avoiding these pitfalls starts with clear and consistent signage.

Too much signage or cluttered layouts can overwhelm employees, making it harder to spot key warnings [14][5]. Research shows people typically have just 3–5 seconds to read and process a sign as they pass it [14]. To enhance readability, ensure the text takes up no more than 20% of the sign’s total space [14]. Also, space out signs with unrelated messages to reduce visual clutter and keep critical information easy to spot.

Using inconsistent fonts, colours, or layouts can delay recognition of safety messages and damage the credibility of your system [14][15]. A unified approach is crucial – standardise signage across your site with consistent layouts and AS 1319-compliant colour schemes for each category of sign [2][15]. When multiple signs are necessary, group them by purpose (e.g., placing all Hazchem warnings together) to minimise confusion [5]. Following AS 1319 guidelines ensures your safety messaging remains uniform and effective.

"Standardise your signage across the site. Clear, consistent, and uncluttered messaging makes expectations obvious and reduces compliance risks."

– Phoenix Graphics [2]

Maintaining signage integrity requires regular upkeep. Assign an officer to inspect, clean, and replace faded or damaged signs, and keep a log to track these activities. Conducting formal signage audits at least twice a year is a good practice to ensure compliance. Additionally, remove outdated or duplicate signs that could obscure current safety protocols [2][4].

PXP Safety provides durable safety signage solutions designed to meet compliance standards. Their signs feature UV-protective film and outdoor-grade printing, ensuring your system stays clear, consistent, and reliable.

Conclusion

Taking care of common signage issues is crucial for keeping your workplace safe and compliant. Problems like faded signs, missing warnings, poor placement, outdated designs, or inconsistent systems can lead to hefty penalties, preventable injuries, or even operational shutdowns. In Australia, businesses can face fines exceeding $100,000 for serious WHS breaches [6]. Non-compliance can also invalidate insurance claims, trigger stop-work orders, and harm your reputation with both clients and staff.

"Safety signage compliance is more than a legal requirement – it’s a lifeline in emergencies."

– Verdex [6]

To avoid these risks, it’s essential to act early. Replace signs that have reached their 3–7 year lifespan [2], and keep a digital logbook of all corrective actions to show due diligence during regulatory reviews [4]. Signs should be mounted at eye level (1.5m to 2.1m) and placed where they’re visible before encountering hazards, not after [4][5].

A reliable and compliant signage system is your best defence against these risks. PXP Safety offers durable, AS 1319-compliant signs made from UV-stable aluminium with outdoor-grade printing, ensuring they stay clear and audit-ready for years. Custom options are available for specific hazards, and all designs meet current regulatory standards – avoiding the pitfalls of DIY or home-printed signs. By choosing a trusted partner like PXP Safety and committing to regular maintenance, you can protect your workplace and ensure ongoing compliance.

FAQs

How often should workplace safety signs be checked for compliance?

Ensuring workplace safety signs are up-to-date is crucial. These signs should be reviewed at least annually to confirm they comply with regulations and remain effective. Additionally, inspections should take place whenever workplace conditions change – such as during renovations, the introduction of new equipment, or when safety regulations are updated.

Regular checks help spot problems like faded text, physical damage, or outdated details. Keeping your signage clear and compliant not only promotes safety but also helps prevent potential hazards or legal penalties.

What risks are associated with outdated or non-compliant safety signs?

Using old or non-compliant safety signs in the workplace can create serious problems. These range from a higher likelihood of accidents to failing audits and even facing hefty fines or legal action. Beyond that, outdated signage can damage trust among employees and regulators, weakening the overall safety culture of your organisation.

To prevent these challenges, it’s crucial to routinely inspect your safety signage and ensure it aligns with Australian standards. Investing in durable, compliant signs not only helps maintain a safer environment but also shows a clear dedication to protecting your team and adhering to legal requirements.

Why are proper placement and sizing of safety signs important for audit compliance?

Ensuring safety signs are properly positioned and appropriately sized is key to meeting Australian standards like AS 1319. These signs must be visible and easy to read from the necessary viewing distance to effectively warn of hazards or convey instructions. Signs that are too small or incorrectly placed can result in non-compliance, which may increase the chances of failing a safety signage audit.

During an audit, inspectors evaluate whether signs are placed where they’re most needed and if their size allows for clear visibility. Getting these details right not only helps you pass audits but also improves safety on site by making sure vital information is accessible to everyone.

Related Blog Posts

You may also be interested in

Safety Sign Colour Guide

Discover the meanings of safety sign colours in Australia with our easy guide. Learn what red, yellow, green, and blue signs mean instantly!

Common Safety Signage Issues and Fixes

Poorly placed, faded or non-compliant safety signs put workers and businesses at risk; this guide explains common issues and practical WHS fixes.

Checklist: Safety Signs for Policy Integration

Audit, update and maintain AS 1319-compliant workplace safety signs: map hazards, assign ownership and schedule inspections for WHS compliance.

Exit Signs vs. Evacuation Route Signs: Key Differences

Compare exit signs and evacuation route diagrams: roles, placement and Australian standards (AS/NZS 2293, AS 3745) for safe transport facilities.

Vehicle Entry Signs for Warehouses

Vehicle entry signs are the frontline defence in Australian warehouses, enforcing AS 1319, separating pedestrians and vehicles to prevent collisions.