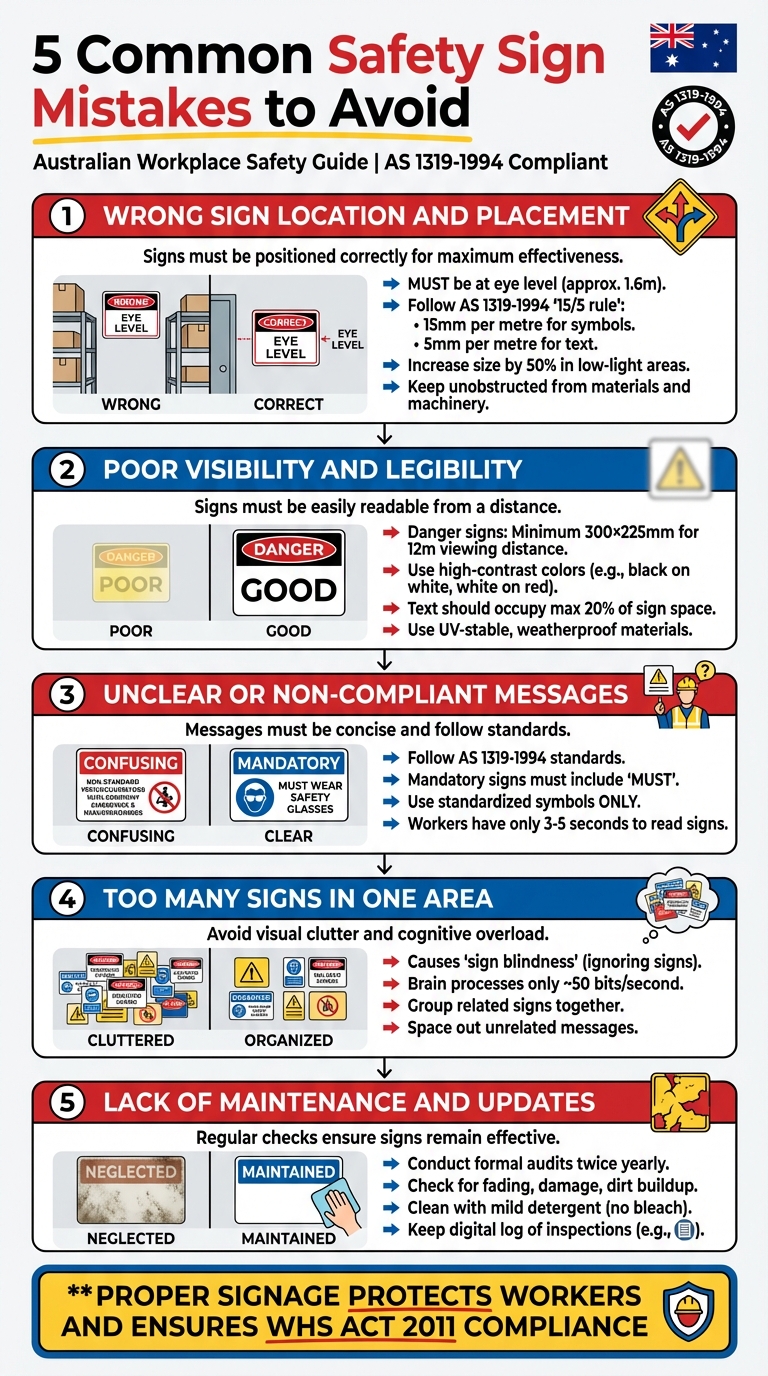

Common Safety Sign Mistakes to Avoid

Safety signage is a legal requirement in Australian workplaces under the WHS Act 2011. Mistakes like poor placement, faded signs, or non-compliance with AS 1319:1994 standards can lead to accidents, fines, and operational delays. Here’s what you need to know:

- Placement Matters: Signs must be at eye level, unobstructed, and positioned at safe distances from hazards.

- Visibility is Key: Use large fonts, high-contrast colours, and durable materials to ensure readability, even in low-light conditions.

- Clear Messaging: Follow AS 1319 standards for symbols and wording to avoid confusion or non-compliance.

- Avoid Overcrowding: Group related signs and space them out to prevent "sign blindness."

- Regular Maintenance: Inspect and clean signs twice a year to keep them legible and compliant.

Proper signage isn’t just about meeting regulations – it protects workers and keeps your site running smoothly. Regular audits and durable materials are essential to maintaining safety and compliance.

5 Common Safety Sign Mistakes to Avoid in Australian Workplaces

1. Wrong Sign Location and Placement

Getting the placement of safety signs wrong can lead to serious risks. For instance, a sign installed too high might fail to alert workers to a hazard below, while one placed too low could become a hazard itself, risking damage or causing injuries [8][9]. According to the Australian Standard AS 1319-1994, signs should be positioned at eye level, aligning with the observer’s line of sight, and set against a contrasting background for maximum visibility [2].

"A person may already be in danger even before they can see the warning and understand it when a sign is placed too close to the intended hazard or danger." – K2K Signs [9]

The distance between the sign and the hazard is just as important as its height. Signs placed too close to a danger give workers little time to recognise the warning and respond. On the flip side, if a sign is too far away, it may lose its relevance, leaving workers unaware of the specific risk. The AS 1319-1994 provides a practical guideline – the ’15/5 rule’: use symbols sized at 15mm per metre of viewing distance and uppercase text at 5mm per metre. For low-light areas, increase these dimensions by 50% [2].

Ensure signs remain unobstructed. Avoid placing them where materials, machinery, or high-traffic zones might block them [8][2]. It’s also wise to consider future developments – like new equipment or site expansions – that could obstruct the sign later on [8]. Position signs at key decision points, such as entrances to hazardous areas or near turn-offs, so workers can act before encountering the danger [6][10].

Don’t overwhelm workers by clustering unrelated signs. This can dilute their effectiveness and create confusion [8][3]. Instead, group signs with related messages together, such as personal protective equipment (PPE) requirements, while maintaining enough spacing for clarity. Emergency exit and first aid signs should always be placed consistently near doors or pathways to avoid any ambiguity [10]. Thoughtful placement like this not only improves visibility but also supports overall site safety management.

2. Poor Visibility and Legibility

Unreadable signs fail to protect workers. Many Australian workplaces still rely on signs with fonts that are too small, colours that blend into the background, or materials that have faded over time. According to AS 1319-1994, pictograms should measure at least 15mm per metre of viewing distance, while uppercase text should be at least 5mm per metre [2][4]. For example, a Danger sign needs to be approximately 300×225mm to ensure it can be understood clearly from 12 metres away [4]. Factors like lighting and colour contrast also play a critical role in determining how effective a sign is.

Ambient lighting has a significant impact on sign readability. In dimly lit areas – such as warehouses, underground car parks, or outdoor sites where natural light fluctuates – symbols and text need to be larger for better visibility. In these situations, reflective finishes or illuminated signs are crucial to maintain legibility in low-light conditions or after dark [1][6].

"If people can’t read your sign, it’s worthless. This fundamental signage mistake stems from prioritising aesthetics over function." – Pinnacle Signage [6]

Using high-contrast colour combinations, like black on white or white on dark backgrounds, ensures that messages are easy to see and read. In contrast, low-contrast pairings, such as light grey on white, can make information nearly invisible from a distance. Clear, uncluttered designs are also essential – text should typically occupy no more than 20% of the total sign space to improve comprehension [6].

Durability is just as important as design and placement when it comes to maintaining a sign’s effectiveness. Exposure to UV radiation and harsh weather can cause signs to fade, crack, or become illegible over time. To combat this, using UV-stable materials like marine-grade aluminium paired with outdoor-grade printing ensures signs remain readable for years. Regular cleaning is also necessary to prevent dirt and grime from obscuring critical information.

For Australian workplaces seeking signage that meets AS 1319-1994 standards, PXP Safety offers compliant, durable, and customisable solutions. Visit their website at https://pxpsafety.com.au to explore their range of workplace signage options.

3. Unclear or Non-Compliant Messages

Confusing language and the use of non-standard symbols can lead to misunderstandings, workplace accidents, and even hefty fines. Take, for example, a generic sign that says "Be Careful." It doesn’t tell workers what specific hazard to watch out for. In contrast, a properly designed warning sign with standardised pictographs communicates the exact danger clearly and effectively. This is why the Australian Standard AS 1319-1994 exists – to eliminate ambiguity by specifying precise colour schemes, shapes, and symbols for each category of safety sign.

The costs of non-compliance can be severe. According to Signsmart, even signs that are almost correct can result in fines [5]. This highlights the importance of ensuring every safety sign delivers a clear and compliant message.

"Non-compliant signs can cause confusion and contribute to accidents." – Pinnacle Signage [6]

To ensure clarity, mandatory signs must include the word "MUST" to indicate required actions. For example, a blue circle with a white pictograph isn’t enough. The message should say something like, "Safety Glasses MUST be worn." Similarly, danger signs are reserved for life-threatening hazards and must feature "DANGER" in white text on a red oval, which is placed within a black rectangle.

Using standardised symbols from the AS 1319 approved list ensures workers can instantly recognise hazards across industries and worksites. Improvised symbols, on the other hand, can create confusion and violate compliance standards. For chemical hazards, signs must also align with the Globally Harmonized System (GHS 7), ensuring consistency both within Australia and internationally. Additionally, safety messages should be concise – occupying no more than 20% of the total sign space – as workers typically have only three to five seconds to read and understand them during emergencies [6].

PXP Safety offers signage that meets AS 1319-1994 standards, using approved symbols and clear messaging. For businesses that need customised solutions while staying compliant with Australian safety regulations, visit PXP Safety to explore options tailored to your needs.

4. Too Many Signs in One Area

When there’s an overload of signs in one spot, their effectiveness can take a hit. Workers might start tuning them out altogether, a phenomenon often referred to as "sign blindness." This happens because the brain can only handle so much visual input at once. In fact, studies show that our conscious mind processes just 50 bits of information per second, meaning too many signs in one area can overwhelm and confuse rather than inform [13]. To combat this, it’s crucial to group and space safety signs thoughtfully.

"With a dozen signs occupying the same space, it’s easy for information overload to kick in, reducing the visual impact – and therefore, the effectiveness – that safety signs have." – Signsmart [8]

Workers generally have only three to five seconds to read and understand a sign. If unrelated messages – like PPE instructions, chemical hazard warnings, and emergency procedures – are crammed together, it becomes harder to identify the most pressing danger [3][9].

To avoid this, organise signs by their purpose. For example, grouping Hazchem, GHS, and Emergency Information Panel signs together ensures chemical risks are communicated clearly [8][3]. Leave enough space between unrelated signs to prevent them from visually blending into one another. Above all, prioritise critical hazards by placing danger and warning signs where they’re most visible, ensuring they don’t get overshadowed by less urgent messages [9].

Safety expert Michael Selinger emphasises, "Signs have limited impact when workers become complacent toward safety measures" [11]. Regularly reviewing and planning signage placement helps keep essential warnings noticeable and effective.

sbb-itb-9950c92

5. Lack of Maintenance and Updates

Once you’ve got the placement and messaging of your safety signs sorted, the next step is just as important: keeping them in good condition. Even the most perfectly positioned sign loses its purpose if it becomes faded, damaged, or grimy. Australia’s challenging conditions – like intense UV rays, salty coastal air, and dusty work sites – can quickly wear down signage. Unfortunately, many businesses fall into the trap of treating signs as a "set and forget" solution [1].

"For maximum effectiveness, safety signs should be maintained in good condition, kept clean and well illuminated." – WorkSafe ACT [2]

This isn’t just about appearances. Signs that fade or deteriorate can lead to non-compliance with AS 1319, which specifies colour standards – like red for danger and yellow for caution. Damaged signs can also fail safety audits. What’s more, if a sign loses its reflectivity, it can become nearly invisible in low-light or emergency situations [1].

To avoid these issues, it’s essential to conduct formal signage audits at least twice a year [1][15]. During these inspections, check for:

- Fading or discolouration

- Physical damage (like cracks or dents)

- Dirt or grime buildup

- Loose or unstable mounting hardware

Cleaning signs regularly is just as important. Use a soft cloth with mild detergent, and steer clear of harsh chemicals like bleach, which can damage the surface [14]. If you need to replace a sign, opt for UV-stable, weatherproof materials like marine-grade aluminium to ensure longevity [1][6].

Keeping a digital log of inspections, repairs, and replacements is a smart way to demonstrate compliance with workplace health and safety (WHS) requirements [14][15]. After all, a safety sign that can’t be seen is a safety sign that can’t do its job [1].

Integrating Safety Signage Into Site Safety Management

Safety signage works best when it’s part of a broader safety strategy. By integrating signs with risk assessments, Safe Work Method Statements (SWMS), and traffic management plans, you can effectively manage hazards across your site. A common pitfall is relying on signage as a standalone measure. As Michael Selinger, Editor-in-Chief of the Health & Safety Handbook, explains:

"A sign on its own cannot be the single safety solution for controlling any particular hazard or risk – it must be used in conjunction with other controls" [11].

This highlights the importance of using signs as a complementary tool to other safety measures.

Aligning Signage with Risk Assessments

Each safety sign should directly address specific hazards identified in your risk assessments. For example:

- Danger signs (white text on a red oval) should be used for life-threatening risks.

- Warning signs (black triangles on yellow) are better suited for moderate hazards.

- Mandatory signs (blue with the word "MUST") enforce required actions, such as wearing PPE.

If your risk assessment concludes that PPE is compulsory, reinforce this with clear blue Mandatory signs that state "MUST".

Traffic Management and Signage

For sites with mobile plant or vehicles, traffic management plans should be mirrored in your signage. Use traffic signs to guide vehicle flow, mark pedestrian exclusion zones, and set speed limits with Restriction signs that comply with AS 1742.1. This is particularly vital for visitors and contractors who may not be familiar with the specific hazards of your site.

Keeping Signage Up to Date

Maintaining a signage register – either digital or physical – is a practical way to track the location, type, and condition of your signs. Assign someone to document each sign’s details, including any required follow-ups. This record-keeping not only supports compliance during audits but also ensures timely replacement of damaged or outdated signs. To stay ahead, conduct formal audits at least twice a year to check for wear, fading, or outdated information.

Choosing the Right Supplier

When sourcing signage, durability and compliance are key. PXP Safety offers a range of workplace safety signs designed for Australian conditions. Their products, made with aluminium, UV protective film, and outdoor-grade printing, are built to withstand harsh weather. Their inventory includes everything from Danger and Mandatory signs to fire equipment and first aid signage, all adhering to AS 1319 standards. For unique site hazards, custom signage options are also available.

Conclusion: Avoiding Common Mistakes for Safer Workplaces

Getting safety signage right isn’t just about ticking boxes – it’s about saving lives. When signs are placed correctly, easy to see, and well-maintained, they play a crucial role in preventing accidents by alerting workers to potential dangers and providing immediate emergency information [2][7]. On the flip side, faded signs or poor placement can leave your business vulnerable to hefty fines under WHS regulations and even legal action [1][6]. Clear signage also helps overcome language barriers, ensuring that every worker, regardless of their background, understands essential safety instructions [11][12].

Using universal symbols and pictographs is key to making safety protocols accessible to everyone. This is especially important for visitors and contractors who may not be familiar with your site’s specific hazards and requirements [3][7].

Regular inspections – whether monthly or quarterly – can help you catch damaged or outdated signs before they turn into compliance issues. Opting for materials like UV-stable, weatherproof marine-grade aluminium ensures that your signage can endure harsh conditions without fading [1][6].

Getting this right does more than just prevent legal troubles – it builds trust. Workers and regulators alike are more confident in a workplace that prioritises clear and effective safety measures. Poor signage, on the other hand, can undermine trust, hurt your reputation, and damage your professional credibility. By focusing on compliance, visibility, and regular upkeep, you’re not just meeting Australian Standards – you’re showing a genuine commitment to your team’s wellbeing.

At PXP Safety, we understand the importance of reliable and durable safety signage. Our customisable solutions are designed specifically for Australian workplaces, helping you avoid common mistakes and strengthen your overall safety strategy. To learn more about how we can support your safety goals, visit us at PXP Safety.

FAQs

What happens if safety signs don’t meet compliance standards?

Using safety signs that don’t meet compliance standards can result in severe repercussions for businesses. These might range from hefty regulatory fines and interruptions to projects, to tarnishing your reputation among workers and regulatory bodies.

Beyond the legal and financial risks, non-compliant signage can significantly raise the likelihood of workplace accidents. When signs are unclear or incorrect, they fail to effectively communicate hazards, putting everyone at risk. Meeting Australian safety standards for signage isn’t just a legal requirement – it’s a critical step in safeguarding your team and steering clear of avoidable penalties.

What can I do to keep my safety signs visible and effective over time?

To keep your safety signs effective and easy to understand, it’s crucial to choose the right materials. Opt for UV-protected aluminium with outdoor-grade printing. These materials are built to handle Australia’s tough weather, including intense sunlight and heavy rain. Pair this with high-contrast colours and large, legible fonts to ensure the signs remain visible, even from a distance.

Placement is just as important as design. Install signs at a height and distance that make them noticeable – typically about 1.5 metres from the hazard. For areas with low lighting, reflective or illuminated signs are a smart choice to maintain visibility. Make it a habit to regularly check your signs for damage, clean off any dirt or grime, and replace those that are faded or worn out.

PXP Safety provides a variety of UV-resistant safety signs that meet compliance standards. Their range includes options for danger, fire equipment, first aid, and mandatory signs, all designed to stay clear and durable in Australian conditions.

Why should safety signs be spaced out properly instead of grouped together?

Too many safety signs grouped together can overwhelm the visual space, making it difficult for workers to quickly spot critical warnings or instructions. This overload can lead to confusion, overlooked hazards, and a decrease in the effectiveness of the signage.

For safety messages to stand out and be effective, it’s essential to place signs thoughtfully, leaving enough space between them to ensure they remain easy to read. This approach helps workers absorb the information quickly and supports adherence to workplace safety guidelines.

Related Blog Posts

You may also be interested in

Safety Sign Colour Guide

Discover the meanings of safety sign colours in Australia with our easy guide. Learn what red, yellow, green, and blue signs mean instantly!

Common Safety Signage Issues and Fixes

Poorly placed, faded or non-compliant safety signs put workers and businesses at risk; this guide explains common issues and practical WHS fixes.

Checklist: Safety Signs for Policy Integration

Audit, update and maintain AS 1319-compliant workplace safety signs: map hazards, assign ownership and schedule inspections for WHS compliance.

Exit Signs vs. Evacuation Route Signs: Key Differences

Compare exit signs and evacuation route diagrams: roles, placement and Australian standards (AS/NZS 2293, AS 3745) for safe transport facilities.

Vehicle Entry Signs for Warehouses

Vehicle entry signs are the frontline defence in Australian warehouses, enforcing AS 1319, separating pedestrians and vehicles to prevent collisions.