How Safety Signs Support Compliance in Training

Safety signs are a legal requirement under the Work Health and Safety Act 2011 and play a key role in protecting workers from hazards, especially during onboarding. They provide clear, visual communication of risks, required actions, and emergency protocols. This is particularly important in workplaces with diverse teams, as standardised symbols help overcome language barriers.

Here’s why they matter:

- Compliance: Meeting Australian Standard AS 1319:1994 ensures businesses adhere to WHS regulations.

- Training Reinforcement: Signs act as constant reminders of safety protocols, bridging gaps left by induction sessions.

- Risk Reduction: Proper signage prevents accidents by clearly marking hazards and safety requirements.

- Emergency Preparedness: Emergency and fire safety signs guide workers during critical situations.

Without effective signage, businesses risk fines, legal issues, and increased workplace accidents. Regular inspections, durable materials, and compliance with standards are essential to maintaining safety and avoiding penalties.

Signage and Demarcation Awareness E-learning

Common Compliance Problems During Employee Onboarding

Many workplaces in Australia still struggle with onboarding processes that fully address safety. A major issue is neglecting to incorporate safety into inductions and failing to clearly explain WHS protocols [3][6]. This oversight leaves new employees vulnerable from their very first day, often unaware of workplace hazards or how to safeguard themselves. Such gaps in induction processes often lead to further shortcomings in training.

When training is inadequate, new employees may remain unaware of obvious risks and how to manage them effectively [3][6]. While they might receive brief instructions – whether verbal or written – this doesn’t guarantee they understand how to perform tasks safely. There’s a big difference between being told about a procedure and being trained to demonstrate competency, but many employers bypass this critical step, jeopardising WHS compliance.

Compliance Risks Without Safety Signs

The absence of proper safety signage amplifies these training gaps. Non-compliant, missing or poorly maintained safety signs are a clear breach of WHS requirements, yet they remain a persistent issue in Australian workplaces [1]. Faded, outdated or damaged signs fail to communicate safety messages effectively, undermining both safety and compliance [1].

In industries like construction, logistics, manufacturing and warehousing – where risks are often high – these visual communication failures can have immediate and dangerous consequences. For instance, missing a ‘Danger’ sign could lead to workers unknowingly entering hazardous areas, while a lack of mandatory signage might result in workers neglecting to wear essential PPE [7]. Without these visual reinforcements to support training, new employees may struggle to identify risks, recognise prohibited actions or locate emergency facilities – all of which are mandatory under the WHS Regulations 2011 [1]. These signage failures only increase the risks for new workers.

How This Affects New Workers and Workplace Safety

When safety signage is inadequate, the risks to new employees multiply. They face a greater likelihood of entering dangerous areas, failing to use necessary safety equipment, or encountering unmarked hazards that more experienced workers might instinctively avoid [7]. In workplaces with diverse teams, the absence of universally recognised safety symbols can create communication barriers, leaving workers with limited English proficiency especially vulnerable [1][9].

Non-compliant signage doesn’t just endanger employees – it exposes businesses to severe legal and financial consequences. Breaches of health and safety duties under the model WHS Act can result in significant fines, regulatory investigations, operational disruptions and reputational harm [7][8][9]. Depending on the severity, these breaches may lead to Category 1, 2 or 3 offences under the law [5]. Emergency preparedness is also compromised, as new workers may struggle to quickly locate emergency exits, first aid stations or firefighting equipment, delaying critical responses when every second counts [1][8].

How Safety Signs Fill Compliance Gaps in Training

Safety signs bridge the gap between theory and practice. While training manuals and spoken instructions can sometimes be missed or forgotten, safety signs provide a constant, visual reminder of critical safety information. Positioned strategically throughout the workplace, these signs act as silent guides, offering immediate and accessible guidance exactly when and where workers need it most [1][4]. They reinforce training by showing workers real-life examples of how to stay safe on the job.

For new employees, safety signs are especially effective in addressing gaps left by onboarding sessions. Rather than relying on memory alone to recall every detail from induction, workers can rely on these signs to quickly identify hazards, required actions, or emergency protocols. For instance, a "High Voltage" sign near electrical equipment or a "Hearing Protection Must Be Worn" notice in noisy areas immediately communicates the risks and necessary precautions [1].

In Australia’s multicultural workplaces, standardised safety signs play an even bigger role. Universal symbols and colours help overcome language barriers. A red circle with a diagonal line universally signals prohibition, while a yellow triangle with a black hazard icon highlights potential dangers [13][14].

Using Visual Aids in WHS Inductions

Safety signs are invaluable during Work Health and Safety (WHS) inductions, turning abstract rules into clear, actionable cues. New employees quickly learn where personal protective equipment is required, where smoking is not allowed, and how to recognise different hazard levels. By consistently encountering these signs, workers develop habits that reinforce safety protocols over time [4].

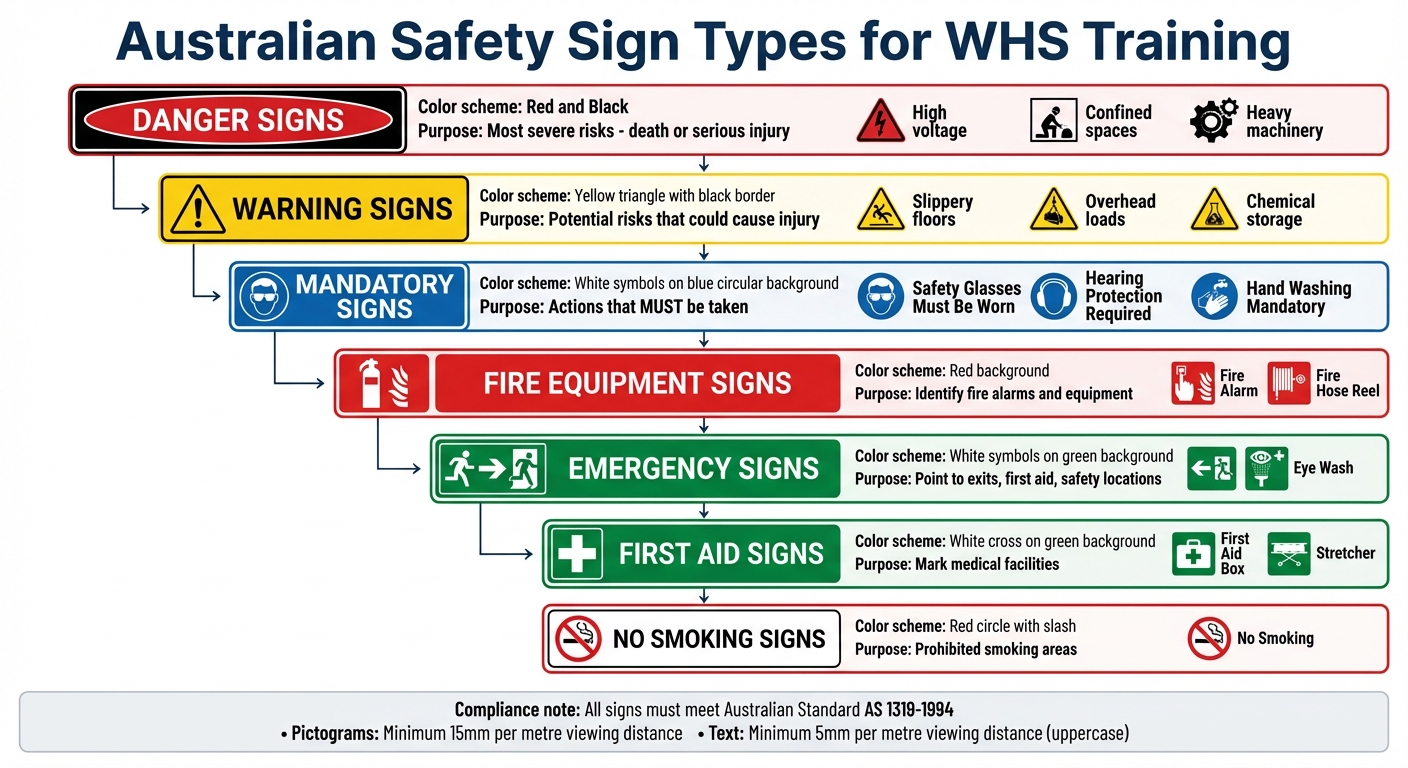

Mandatory signs, featuring white symbols on blue circular backgrounds, clearly indicate behaviours that must be followed. Warning signs, designed as yellow triangles, alert workers to potential hazards, while emergency signs – white symbols on green backgrounds – guide them to first aid stations, emergency exits, or safety equipment. These visual aids not only strengthen training but also ensure compliance with safety regulations from the very first day [11][13].

Meeting Australian Safety Standards

Filling training gaps with safety signs also ensures compliance with Australian safety standards. The Australian Standard AS 1319-1994 outlines precise requirements for the design, colour, size, and format of safety signs [10][2][11][12]. This standardisation guarantees that danger signs are consistent and easy to understand across all Australian workplaces, allowing workers to interpret them instantly based on their training.

Under the Work Health and Safety Act 2011 and its regulations, compliance with AS 1319-1994 is a legal obligation [1][11]. For example, pictograms on signs must measure at least 15 mm per metre of viewing distance, while uppercase text must be at least 5 mm per metre, ensuring readability [2]. When safety signs meet these standards, they not only help employers meet their legal responsibilities but also provide new workers with the clarity and confidence they need during their initial weeks on the job [14][1].

sbb-itb-9950c92

Key Safety Sign Types for Training Programs

Australian Safety Sign Types and Standards Guide for WHS Compliance

Addressing compliance gaps in workplace safety requires a variety of safety signs to ensure effective WHS training. According to Australian standards, safety signs are grouped to prevent accidents, highlight potential hazards, guide safety behaviours, and convey essential safety information [15]. These categories are the backbone of a strong WHS training program, helping new employees quickly identify and respond to workplace risks.

Using the right combination of signs transforms abstract safety rules into clear, actionable instructions. WHS signs and symbols provide critical safety information and support alignment with Australian safety regulations [15]. During onboarding, these visual aids help trainers explain safety protocols in practical terms, making compliance easier to grasp and remember.

Danger, Warning, and Mandatory Signs

Danger signs are marked by red and black colours to signal the most severe risks – those that could lead to death or serious injury. You’ll often find these signs near high-risk areas like electrical installations, confined spaces, or heavy machinery. For new workers, these signs deliver immediate and unambiguous warnings, ensuring they understand the gravity of certain hazards [1].

Warning signs, featuring yellow triangles with black borders, alert workers to potential risks that could cause injury if precautions aren’t taken. These might include slippery floors, overhead loads, or chemical storage areas. Their high visibility ensures workers can spot them even in less-than-ideal conditions.

Mandatory signs use white symbols on blue circular backgrounds to indicate actions that must be taken. Examples include "Safety Glasses Must Be Worn", "Hearing Protection Required", or "Hand Washing Mandatory." These signs are essential for embedding safety practices into daily routines, offering clear reminders wherever protective actions are required [1].

Fire Equipment and Emergency Signs

Fire and emergency signs are designed with clear, colour-coded backgrounds – red for fire equipment and green for emergency facilities. Fire safety signs identify fire alarms and equipment, while emergency signs point to exits, first aid stations, and other critical safety locations [16].

During inductions, these signs play a vital role in teaching new employees how to respond quickly in emergencies. They also support evacuation drills and ensure preparedness is prioritised. The Model Code of Practice: First Aid in the Workplace and the Model Code of Practice: Managing the Work Environment and Facilities outline specific requirements for emergency exits and fire safety signage, reinforcing their regulatory importance. Incorporating these signs into WHS inductions equips workers with the practical knowledge needed to handle emergencies effectively [15].

First Aid and No Smoking Signs

First aid signs, featuring a white cross on a green background, mark essential medical facilities, ensuring quick access to assistance when needed [15].

No smoking signs, with a red circle and slash, clearly indicate areas where smoking is prohibited, reducing fire risks and promoting a safer environment.

These signs work together to uphold workplace safety rules, contributing to a safer work environment and fostering a culture of safety awareness [15].

For high-quality, durable safety signage that aligns with Australian standards, organisations can rely on PXP Safety. They offer a customised range of solutions designed to meet workplace safety requirements effectively.

Adding Safety Signs to WHS Training Programs

Incorporating safety signs into WHS training brings safety rules to life. SafeWork NSW advises that safety measures should be part of new worker inductions before they even start their roles. This ensures employees understand safe work practices and can identify hazards from the outset.

Under the WHS Act 2011, visible safety signs are a legal requirement, playing a key role in risk management [1]. Training programs that include clear, well-explained safety signs help workers recognise hazards, understand required behaviours, and follow emergency procedures, improving compliance across the board.

Including Signs in Training Methods

During site tours, point out signs like ‘High Voltage,’ ‘Slippery When Wet,’ and ‘Danger: Asbestos,’ explaining the hazards they highlight and how to mitigate risks. Similarly, use images of mandatory signs – such as ‘Hearing Protection Must Be Worn‘ or ‘No Smoking‘ – in presentations and toolbox talks to reinforce safe work practices. Incorporating internationally recognised symbols is also an effective way to overcome language barriers, ensuring every worker receives the same critical safety messages. This hands-on explanation naturally leads to assessing how well employees apply these lessons on the job.

Monitoring Compliance and Sign Usage

Once safety signs are part of the training, it’s crucial to evaluate their impact. Use checklists during inductions to record how well workers recognise and understand safety signs, which can also serve as a resource for compliance audits. Regularly review and update signs to reflect changes in workplace conditions, such as new equipment installations. This helps avoid issues like outdated information or signs that are hard to see.

Using Durable and Custom Signs

Durability is a key factor in ensuring safety signs remain effective, especially in challenging environments. For outdoor use, metal signs are a great option as they resist corrosion, sun damage, and harsh weather conditions. For indoor settings, polycarbonate signs offer excellent durability [17]. Damaged or faded signs can create confusion, particularly in emergencies – for example, a blurry ‘Emergency Exit‘ sign during an evacuation could lead to delays [18].

PXP Safety offers durable aluminium signs with UV protection and outdoor-grade printing. These signs are built to last and meet Australian Standard AS 1319:1994. They also provide custom sign options tailored to specific workplace needs, making safety communication more relevant and reducing the need for frequent replacements [4] [18]. Conducting regular inspections and promptly replacing damaged signs ensures they remain effective. Involving employees in the selection and placement of these signs can also promote a sense of shared responsibility, strengthening the workplace safety culture throughout the induction process.

Conclusion

Safety signs play a crucial role in bridging compliance gaps by providing instant hazard recognition, clear instructions, and emergency guidance. They deliver immediate visual communication, helping new employees grasp safety protocols from their very first day. This is particularly important in Australia’s diverse workplaces, where internationally recognised symbols help overcome language barriers and ensure consistent safety messaging.

However, the effectiveness of safety signs depends heavily on their quality and durability. Signs that are faded or damaged not only increase the risk of accidents but also expose businesses to significant liabilities. Under the Model WHS Act, non-compliance with signage regulations can lead to fines exceeding $100,000 for businesses, with penalties for corporations reaching upwards of $3 million [7][19].

PXP Safety offers durable, customisable aluminium signs with UV protection, designed to withstand harsh Australian conditions while meeting the Australian Standard AS 1319:1994. These signs ensure clear and lasting safety communication [7][19].

To maintain compliance and protect employees, regular inspections, staff training, and timely updates to signage are essential. Data from Safe Work Australia in 2024 highlights the importance of these measures, revealing that 23% of workplace fatalities occurred in the construction industry [19]. Effective safety communication is key to addressing such risks and fostering a proactive safety culture.

FAQs

How do safety signs help with training new employees?

Safety signs play a crucial role in workplace training by delivering important safety messages through straightforward, universally recognised visual cues. In Australia, these signs must adhere to the AS 1319-1994 standard, ensuring a consistent design and meaning across all workplaces. By using easily identifiable symbols and colours, these signs allow new employees to quickly grasp necessary actions without the need for lengthy explanations.

Beyond initial training, safety signs serve as constant reminders, reinforcing safety practices and drawing attention to hazards exactly where they occur. This is especially valuable in workplaces with a diverse team, as it reduces reliance on language skills and helps employees retain safety information. PXP Safety provides an extensive selection of AS 1319-compliant signs, enabling businesses to seamlessly incorporate them into onboarding programs and promote a strong safety culture right from the start.

What happens if safety signs don’t meet compliance standards?

Failing to use proper safety signs can result in violations of Australia’s Work Health and Safety (WHS) regulations. This could lead to severe outcomes, including fines, legally enforceable notices like improvement or prohibition notices, and even potential prosecution.

Using compliant safety signs is essential for safeguarding both employees and visitors while ensuring your workplace adheres to legal standards. By choosing durable, high-quality signage, you not only reduce the risk of penalties but also show a strong dedication to maintaining safety and compliance.

How do safety signs help overcome language barriers in diverse Australian workplaces?

Safety signs are essential for overcoming language barriers, thanks to their use of universally recognised symbols. Think of a hard hat symbol indicating mandatory head protection or flames representing fire hazards. These visuals deliver critical safety messages instantly, making them understandable to workers regardless of their native language.

In Australia’s culturally and linguistically diverse (CALD) workforce, bilingual or multilingual signs take this a step further. By pairing clear symbols with brief text translations, employers can ensure safety instructions are accessible to everyone – whether they speak English, Mandarin, Arabic, or any of the many languages spoken nationwide. This not only helps meet WHS requirements but also creates a more inclusive and secure workplace for all employees.

Related Blog Posts

You may also be interested in

Safety Sign Colour Guide

Discover the meanings of safety sign colours in Australia with our easy guide. Learn what red, yellow, green, and blue signs mean instantly!

Common Safety Signage Issues and Fixes

Poorly placed, faded or non-compliant safety signs put workers and businesses at risk; this guide explains common issues and practical WHS fixes.

Checklist: Safety Signs for Policy Integration

Audit, update and maintain AS 1319-compliant workplace safety signs: map hazards, assign ownership and schedule inspections for WHS compliance.

Exit Signs vs. Evacuation Route Signs: Key Differences

Compare exit signs and evacuation route diagrams: roles, placement and Australian standards (AS/NZS 2293, AS 3745) for safe transport facilities.

Vehicle Entry Signs for Warehouses

Vehicle entry signs are the frontline defence in Australian warehouses, enforcing AS 1319, separating pedestrians and vehicles to prevent collisions.