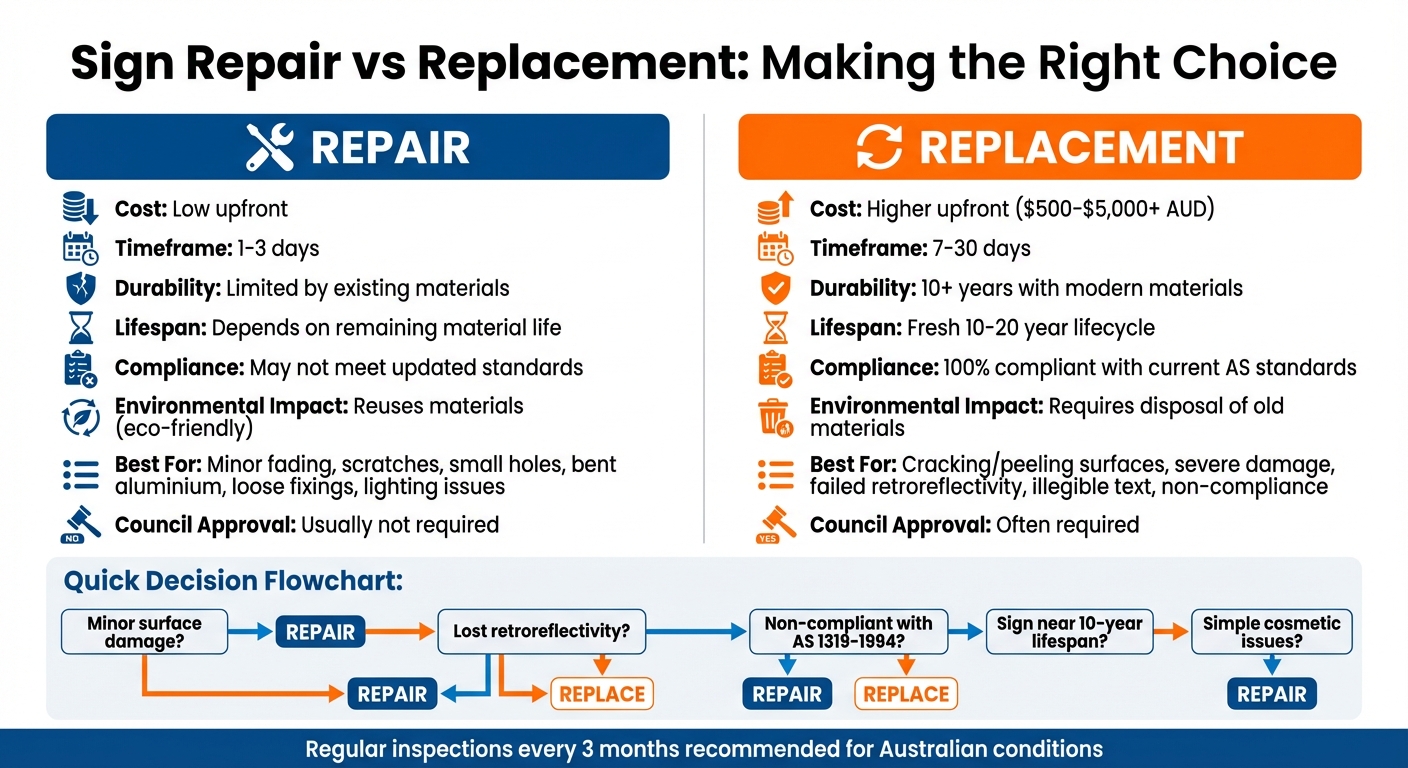

Sign Repair vs Replacement: Key Differences

When workplace safety signs are damaged, the decision to repair or replace depends on factors like cost, durability, and compliance with Australian standards (AS 1319-1994). Repairs are ideal for minor issues like scratches, dirt, or bent frames, while severe damage or non-compliance often requires replacement. Regular inspections and material quality are crucial for long-term savings and safety.

Key Takeaways:

- Repair: Cheaper upfront, quicker (1–3 days), eco-friendly, but less durable and may not meet updated standards.

- Replacement: Higher initial cost, slower (7–30 days), but ensures compliance, longer lifespan (10+ years), and lower maintenance.

Quick Comparison:

| Factor | Repair | Replacement |

|---|---|---|

| Cost | Low upfront | Higher upfront |

| Timeframe | 1–3 days | 7–30 days |

| Durability | Limited by existing materials | 10+ years |

| Compliance | May not meet updated standards | Fully compliant |

| Eco Impact | Reuses materials | Requires disposal of old materials |

For minor damage, repairs save money and time. For extensive damage or outdated signs, replacement is the smarter long-term choice. Regular inspections and choosing durable, UV-resistant materials can help Australian businesses maintain safe, compliant signage.

Sign Repair vs Replacement Comparison Chart for Australian Businesses

Refurbishing Traffic Signs

When to Repair Signs

Repairing signs can be an affordable way to extend their lifespan, helping Australian businesses save money while staying compliant with safety standards. Knowing which signs are worth fixing is key to making the right decision.

Signs That Can Be Repaired

Surface-level damage like minor fading, scratches, or dirt is often the easiest to address. Cleaning and applying UV-resistant films can restore the sign’s appearance and remove surface imperfections [9].

Physical deformation, such as bending or twisting, is another issue that can typically be fixed. For example, bent aluminium signs can be carefully straightened using the right tools, ensuring the reflective sheeting remains intact. Small holes caused by vandalism or impacts can be patched using matching retroreflective sheeting and sealed with aluminium foil tape to keep moisture out [6][10].

Mounting and structural problems are often mistaken for irreparable damage. Issues like loose screws, worn-out fixings, or sagging can be resolved by tightening or reinforcing the sign’s structure [1][8]. For illuminated signs, flickering or dim LEDs often just require replacing bulbs or modules rather than a full replacement [1][9].

Graffiti and spray paint can also be removed with specialised cleaners, but avoid abrasive tools like steel wool, which can damage reflective surfaces [6][10]. Ultimately, the test for repairability lies in the sign’s legibility – if the message is still clear after cleaning or straightening, the sign is a good candidate for repair [6][10].

Now, let’s weigh the pros and cons of repairing a sign.

Advantages and Disadvantages of Repair

Advantages:

- Cost savings: Repairs are often far cheaper than replacing a sign, saving businesses a significant amount [8].

- Quick fixes: Many repairs can be completed on-site within just a few days, reducing downtime [3].

- No council approvals: Fixing an existing sign usually avoids the lengthy approval process required for new installations [2].

- Eco-friendly: Repairing reuses existing materials, reducing waste and contributing to sustainability [6][10].

- Preserves brand image: Quick repairs help maintain a professional appearance, avoiding the negative impression of a damaged sign [2][8].

Disadvantages:

- Shorter lifespan: Repaired signs may not last as long as new ones, especially if the base material is already worn [1].

- Compliance risks: Poor repairs that don’t fully restore retroreflectivity could result in non-compliance with AS 1319-1994 standards [6][10].

- Labour-intensive: Complex repairs requiring significant time and effort may end up costing more than a replacement [6][10].

- Not suitable for severe damage: Signs with extensive structural issues, extreme fading, or heavily compromised sheeting are beyond repair [10].

"Refurbishing a sign is more cost effective than replacing it, and, it allows you to bypass the council approval processes necessary if you order an entirely new unit." – TC Signs [2]

Repair Comparison Table

| Factor | Details |

|---|---|

| Cost Range | A fraction of replacement costs; much cheaper than new signs [8] |

| Timeframe | 1–3 days for most repairs; often completed on-site [3] |

| Best For | Minor fading, scratches, small holes, bent aluminium, loose fixings, lighting issues [6][9] |

| Durability | Limited to the remaining lifespan of the materials [1][9] |

| Compliance | Meets AS 1319-1994 standards if retroreflectivity is restored [6][10] |

| Regulatory | Usually avoids council approval processes [2] |

| Sustainability | Minimises waste by reusing existing materials [6][10] |

When to Replace Signs

While repairs can address minor damage, there are times when replacing a sign is simply the wiser choice. Knowing when to opt for replacement rather than repair can save money over time and ensure your workplace stays compliant with Australian safety standards. Here’s a closer look at when a full replacement makes more sense.

Signs That Need Replacement

Loss of retroreflectivity is a major reason to replace a sign. A sign may appear fine in daylight but become unreadable at night if its reflective sheeting has deteriorated. To test this, try a flashlight test: stand about 10 metres away, hold a flashlight at eye level, and shine it on the sign. If the reflection is poor, the sheeting has lost its effectiveness and needs replacing [6][10].

Surface integrity failure happens when the sign face is severely damaged. Signs with cracking, splitting, peeling, or separation of the sheeting material are no longer fit for purpose and should be replaced [10].

Severe physical damage – such as bending, impact holes, or vehicle collisions – often makes repairs impractical. The United States Department of Transportation notes:

"More often than not, it is cheaper to replace a badly damaged or unreadable sign than attempt many repairs" [10].

Illegibility is a dealbreaker for safety signs. Replace any sign with faded colours, dimmed lighting, or damaged text to maintain clear readability [4][6].

Structural and mounting issues also call for replacement. Signs that twist, flex, or have deteriorating frames are no longer reliable. If the fascia is degraded and can’t support the sign, replacement or reinforcement is necessary [1].

Non-compliance with updated Australian safety standards is another clear sign it’s time for a replacement. Signs that fail to meet current standards – such as AS 1742 for traffic control devices – or feature outdated branding should be replaced to ensure legal and professional compliance [4][6][11].

Now, let’s weigh the pros and cons of replacing signs.

Advantages and Disadvantages of Replacement

Advantages:

- Longer lifespan: New signs generally last up to 10 years, effectively starting fresh with a new service life [1].

- Compliance assured: Replacement ensures the sign aligns with the latest Australian safety and legal standards, including AS 1742 [11].

- Modern materials: New signs incorporate UV-resistant materials and advanced LEDs designed for Australian conditions [4].

- Professional image: A new sign enhances your business’s appearance and reputation [2].

- Low maintenance: Replacing a sign reduces the need for ongoing repairs [1].

Disadvantages:

- Higher initial cost: Replacing a sign is more expensive upfront compared to minor repairs [2].

- Time delays: Manufacturing and installation can take between 7 and 21 days [11].

- Disposal challenges: Old signage materials need to be properly recycled or discarded.

- Council permits: New signage may require additional approvals from local councils [2].

"Dirty, broken or faded signs send the wrong message: you don’t care about your business or image, so why would you care about your client?" – TC Signs [2]

Replacement Comparison Table

| Factor | Details |

|---|---|

| Cost Range | $500–$5,000+ AUD depending on size and type; LED upgrades: $2,000–$15,000+ AUD [11] |

| Timeframe | 7–21 days for standard signs; 14–30 days for LED installations [11] |

| Best For | Cracking/peeling surfaces, severe bends, failed retroreflectivity, illegible text, and non-compliance [4][6][10] |

| Durability | 10+ years with modern materials and proper installation [1] |

| Compliance | 100% compliant with current Australian Standards (AS 1742, AS 1743, AS 2890) [11] |

| Long-term Savings | High; replacement reduces frequent maintenance visits and legal liability risks [11] |

| Sustainability | While new signs last decades, proper disposal of old materials is required |

Cost Comparison: Repair vs Replacement

When weighing up the costs of repairing versus replacing a sign, it’s important to look beyond the initial price. Repairs might seem cheaper at first glance, but ongoing fixes can eventually add up to more than the cost of a brand-new sign. Alan Hadley, Director at SignManager, explains it clearly:

"A poorly designed sign can cost up to five times as much as a well-designed sign due to spiralling maintenance costs" [13].

Given that most signs have an expected lifespan of around 10 years [1], repairing one that’s nearing the end of its life often results in diminishing returns and a higher chance of failure [13]. On the other hand, replacing a sign starts a fresh lifecycle, often providing 10–20 years of service with materials designed to withstand Australia’s tough conditions [13].

What Affects the Cost

Breaking down the factors that influence costs can help determine whether repair or replacement offers better value. Here’s what plays a key role:

- Size and Material: Larger signs naturally require more resources and labour. While aluminium signs with UV protection may cost more upfront, they’re built to last longer under harsh weather [13].

- Accessibility: Signs that need specialised equipment like cranes or high-reach lifts, or a two-person team, can significantly increase labour costs [13].

- Environmental Conditions: Coastal signs often require salt-resistant materials, while those near trees may need frequent cleaning to deal with sap or pollen [12][13]. Industrial areas with pollution or acid rain can also accelerate wear and tear, particularly on horizontal surfaces [12].

These factors often lead to frequent repairs, which can indicate deeper problems like moisture damage, structural issues, or material wear. In such cases, replacement might be the smarter and more economical choice over time [17]. Additionally, repairs usually avoid the need for new council permits, which is another consideration [2].

Cost Comparison Table

| Factor | Repair / Refurbishment | Full Replacement |

|---|---|---|

| Upfront Cost | Low (e.g., cleaning, patching, or component swaps) | High (includes design, fabrication, and installation) |

| Council Approval | Usually not required [2] | Often requires new permits, adding time [15] |

| Long-term Cost | Moderate to high (frequent repairs can add up) [13] | Lower (modern materials and warranties reduce costs) |

| Timeline | Quick (hours to days) [17] | Slower (7–30 days for fabrication and installation) [15] |

| Lifecycle | Limited; diminishing returns after ~10 years [1][13] | Resets lifecycle, offering 10–20 years of service [13] |

| Compliance | May fail to meet updated standards | Fully compliant with current Australian Standards [14] |

| Environmental | Lower impact (reuses existing structure) [17] | Higher impact (requires disposal of old materials) |

| Energy Efficiency | Depends on existing components | High (modern LED options cut running costs) [16] |

sbb-itb-9950c92

Process and Material Differences

Repair and Replacement Steps

Repairing a sign begins with a thorough inspection to identify defects, structural issues, or diminished retroreflectivity [5]. The process usually involves cleaning the sign face with non-abrasive methods to remove dirt and grime [6]. Bent sections are carefully straightened using hand pressure or a rubber mallet, with a protective cloth placed over the reflective sheeting to avoid damage [10]. Scrapes or holes are patched by cleaning the affected area with solvents like Xylol or Varnish Naphtha, applying matching retroreflective sheeting, and sealing it with aluminium foil tape to keep moisture out [10]. For illuminated signs, outdated fluorescent tubes are commonly replaced with LED modules to enhance brightness and improve energy efficiency [7].

Replacement, on the other hand, follows a different process. It begins with design planning to ensure the sign aligns with branding, is easy to read, and complies with local signage regulations [7]. In Australia, this often includes obtaining engineering documents such as Form 15 or Form 16 from local councils [7]. After receiving the necessary approvals, a new sign is fabricated using fresh blanks and specified materials [1]. The installation process involves securing the sign with proper drainage and anti-theft fasteners, such as expanding anchor bolts or blind rivets [10]. Susie Greenwood from Cygnia Maintenance highlights the importance of proper installation:

"A sign that is not secured properly will fall down. If it is not sealed to stop water ingress, and has properly designed drainage, it will become dangerous." [1]

In cases where repair would require extensive labour, replacing the sign might be the more cost-effective option. With these procedures in mind, the next step is selecting materials that can withstand Australia’s unique conditions.

Materials for Australian Conditions

Choosing the right materials is essential to ensure durability in Australia’s challenging environment. Aluminium is the top choice for outdoor signage due to its excellent resistance to rust, corrosion, and weathering [18]. Its low weight – about one-third that of steel – makes it ideal for large installations, as it reduces transport and handling challenges [19]. For added durability, anodised aluminium enhances protection by thickening the natural oxide layer, while aluminium composite panels (ACP/Dibond) offer a lightweight yet sturdy option for sign trays and cladding [19].

When repairing or overlaying graphics, high-grade vinyl with UV-resistant inks is critical to prevent peeling and fading under Australia’s intense sunlight [18]. While PVC is moisture-resistant and immune to rot, it tends to fade quickly in strong UV light, making it less suitable for long-term outdoor use [18]. Whether repairing or replacing, ensuring effective UV protection is key to extending the lifespan of signage [1].

For example, PXP Safety produces workplace safety signs using high-quality aluminium combined with UV-protected inks and outdoor-grade printing. This ensures their signs remain compliant and durable, even in harsh Australian conditions.

How to Decide: Repair or Replace?

How to Assess Sign Damage

Regular inspections are key to keeping your signage in good condition. Aim to check your signs quarterly, focusing on compliance, readability, and structural soundness [1]. Look for issues like cracked paint, peeling vinyl, or bent frames. If a sign flexes or twists, it may point to mounting problems or damage to the sub-fascia [1].

For retroreflective signs, a simple night-time test can help. Stand about 9 metres away and hold a torch at eye level. If the sign looks dull or hard to read compared to a new panel – or fails a spotlight test using 200,000 to 400,000 candlepower from a distance of 30 to 60 metres – it’s likely that the retroreflective sheeting has deteriorated [10]. For electrical signs, watch out for water ingress, flickering lights, or uneven illumination. Spotting these issues early can save you from costly replacements down the line [13].

Taking care of immediate repairs is important, but thinking ahead about your signage strategy can save time and money in the long run.

Planning for Long-Term Signage Needs

Once you’ve assessed the current condition of your signs, it’s time to think about the bigger picture. Consider the total cost of ownership over a five-year period, rather than just focusing on upfront repair or replacement costs [1][13]. Signs generally last between 10 and 15 years [1][13], so if yours are nearing the end of their lifespan, replacing them might be the smarter financial move. Keep track of each sign’s location, installation date, and maintenance history in a database. This will help you know exactly when a sign has reached the end of its useful life [13].

Choosing the right materials can make a big difference, especially in Australia’s tough weather conditions. Maintenance costs for large sign portfolios can run over $10 million annually [13], so it’s worth investing in durable materials. High-quality aluminium with outdoor-grade printing and UV protection is a solid choice. These materials not only extend the life of your signs but also reduce the need for frequent repairs. For example, PXP Safety’s workplace safety signs are specifically designed to handle Australia’s intense UV exposure and challenging weather, ensuring they stay compliant and reliable over time. By planning ahead and choosing durable materials, you can keep your signage effective and cost-efficient for years to come.

Conclusion

Choosing whether to repair or replace your workplace safety signs depends on factors like the extent of damage, compliance requirements, and long-term costs. Minor issues such as dirt, scratches, or slight bending can often be fixed. However, signs with cracks, significant fading, or lost retroreflectivity usually need to be replaced. As the U.S. Department of Transportation advises:

"More often than not, it is cheaper to replace a badly damaged or unreadable sign than attempt many repairs" [10].

Australia’s harsh environmental conditions – like intense UV exposure, high humidity, and frequent storms – make material selection especially important. Outdoor safety signs should be made from durable, UV-resistant materials to ensure a longer lifespan. Conducting regular inspections, ideally every three months, can help identify small issues before they turn into expensive replacements [9].

Compliance is non-negotiable. Your signs must align with Australian workplace safety standards to protect employees and avoid legal risks. If a sign fails to meet current regulations, it must be replaced, even if it appears to be in good condition [9].

When making your decision, think beyond the upfront cost. Consider the total cost over five years, factoring in maintenance expenses, potential safety risks, and the effect on your organisation’s professional image. PXP Safety’s workplace safety signs are designed to handle Australia’s tough climate, featuring durable aluminium construction, outdoor-grade printing, and UV protection to help you stay compliant and cost-effective. These steps will ensure your safety signage strategy is both practical and reliable.

FAQs

How do I know if my sign needs repairing or replacing?

To figure out whether your sign needs a repair or a full replacement, start by giving it a thorough inspection. Keep an eye out for fading, cracks, peeling paint, or damaged graphics – all of which can hurt its readability and professional look. If your sign is illuminated, check for issues like flickering lights or faulty wiring. Minor problems, like surface wear, a single burnt-out bulb, or no structural damage (e.g., bent frames or loose bolts), can usually be fixed without too much hassle or expense.

On the other hand, if the damage is more serious – think extensive fading, large cracks, broken mounting hardware, or anything that could pose a safety risk – replacement is likely the smarter move. Signs that don’t meet current Australian safety standards or reflect an outdated brand image should also be swapped out to ensure compliance and maintain a polished appearance.

For businesses in Australia, choosing durable, UV-protected aluminium signs from PXP Safety can help reduce the need for constant repairs or replacements. These signs are built to handle tough weather conditions while staying in line with local regulations, offering a long-lasting and low-maintenance solution.

What risks could arise if I repair a safety sign instead of replacing it?

Repairing a damaged safety sign might seem like a quick fix, but it can lead to non-compliance with Australian standards like AS 1319 and other workplace safety regulations. This could expose businesses to penalties, legal risks, or even accidents caused by unclear or unreadable signage.

Repaired signs often fail to meet durability expectations, particularly in outdoor settings where they are exposed to harsh weather conditions. This makes them more vulnerable to further damage, reducing their effectiveness and potentially putting safety at risk. Opting to replace the sign ensures it remains compliant, durable, and clearly visible, offering long-term reliability and safeguarding your workplace.

What are the best materials for durable signs in Australia’s tough weather conditions?

For signage built to endure Australia’s tough weather conditions, aluminium, including aluminium composite panels, stands out for its strength and rust resistance. UV-coated vinyl is another excellent option, protecting against fading caused by intense sunlight. Other reliable materials include acrylic, high-density urethane (HDU), and polycarbonate, all known for their durability and ability to withstand harsh environments.

When choosing the right material, consider how much exposure the sign will have to UV rays, rain, and temperature changes. This helps ensure your sign stays legible and functional for years to come.

Related Blog Posts

You may also be interested in

Safety Sign Colour Guide

Discover the meanings of safety sign colours in Australia with our easy guide. Learn what red, yellow, green, and blue signs mean instantly!

Common Safety Signage Issues and Fixes

Poorly placed, faded or non-compliant safety signs put workers and businesses at risk; this guide explains common issues and practical WHS fixes.

Checklist: Safety Signs for Policy Integration

Audit, update and maintain AS 1319-compliant workplace safety signs: map hazards, assign ownership and schedule inspections for WHS compliance.

Exit Signs vs. Evacuation Route Signs: Key Differences

Compare exit signs and evacuation route diagrams: roles, placement and Australian standards (AS/NZS 2293, AS 3745) for safe transport facilities.

Vehicle Entry Signs for Warehouses

Vehicle entry signs are the frontline defence in Australian warehouses, enforcing AS 1319, separating pedestrians and vehicles to prevent collisions.